By Sikla UK Oceania on 03 October 2025

DUALSHIELD, Sikla’s new coating for C5 environments, offers first-class corrosion protection but only when applied correctly!

Ensuring that your steel structure has the correct protection for its intended environment can not only prevent steel corrosion, but it can also significantly reduce its longevity which will cost more for maintenance repairs and increase safety risks.

With careful research, planning and execution these risks can be avoided. Read here 5 common challenges faced with selecting the right corrosion protection for your C5 environment.

1. C5H coating installed in a CX environment

Problem: A C5H coating is designed for very high corrosion exposure in industrial environments. When the coating is used in a CX environment, the highest corrosion category according to ISO 12944 (extreme exposure in offshore areas, tropical coastal areas or chemically aggressive environments), the protective effect of the C5H coating may not be sufficient to withstand these extreme conditions over a long period.

Consequence: Overtime the C5H coating can develop microcracks or pores more quickly under the CX environments. The cracks and pores allow moisture and aggressive substances to penetrate the coating which accelerates the corrosion of the base material, reducing durability.

Solution: Select a coating which suits the environmental condition in order to prevent damage. The environment should be checked in advance and the microclimate should be assessed as accurately as possible.

2. Damage to the coating during transport or assembly

Problem: Beams and other steel components are often transported with insufficient packaging or assembled with unsuitable tools on-site. Both of these practices can easily damage coatings.

Consequence: If unnoticed, the damaged areas become exposed to the corrosive environment. The protection is then compromised allowing rust to form under the coating and accelerate the corrosion process.

Solution: DUALSHEILD products are protected during transport with padding. For installation, Sikla suggest using tools that avoid direct contact with the coating.

Any damaged areas should be repaired immediately, at the latest after installation.

3. Failure to touch up cut edges

Problem: When cutting the material, the uncoated surface becomes exposed and these areas are not touched up.

Consequence: The unprotected edges become susceptible to corrosion and reduce the service life of steel structure.

Solution: All cut edges must be treated with Sikla's touch-up spray paint.

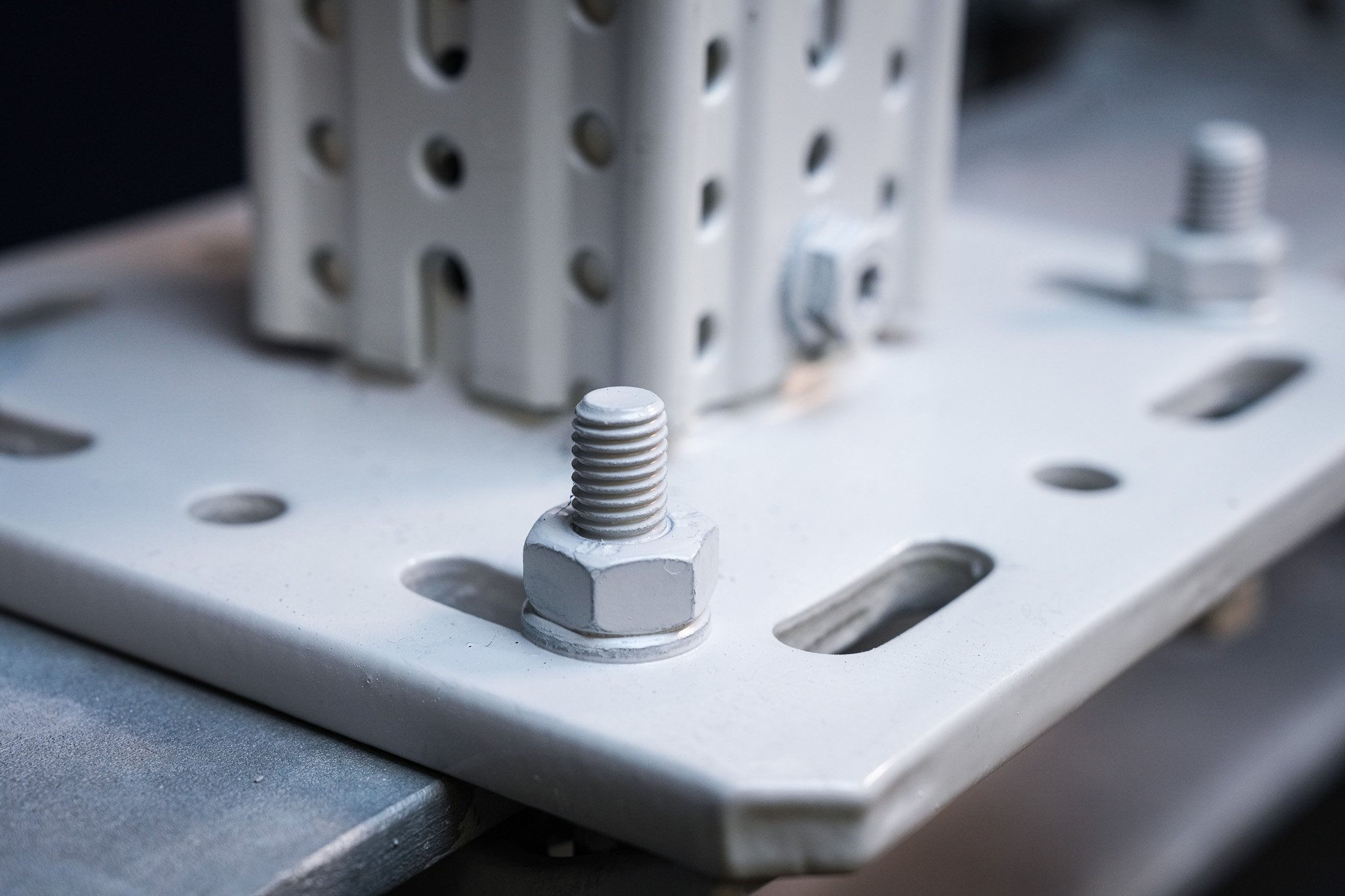

4. Inadequate finishing of threaded parts and components that cannot be coated

Problem: Not all components can be coated, for example threaded parts or elements, that cannot be coated due to their design.

Consequence: The unprotected parts are particularly susceptible to corrosion, which shorten the service life of the steel structure.

Solution: All threaded parts and components that cannot be coated due to their design must be treated with touch-up spray paint after assembly.

5. Failure to make improvements when changes are made to the original design

Problem: If the original design is changed, damage may occur to products with C5H coating applied. For example, if pipe supports are heigh adjusted or the position of the screws are moved.

Consequence: The damaged areas become exposed to corrosion, thereby reducing the service life of the steel structure.

Solution: All products with damaged areas must be treated with touch-up spray paint once the adjustment has been made.

Conclusion: Masterful solutions for your long-lasting construction

The challenges of working with coated materials can be complex, but with the right strategies and expertise, they can be successfully overcome.

With a clear plan and precise implementation, we ensure that DUALSHIELD not only meets all requirements of C5 environments but also provides long-term protection.

To avoid the most common mistakes when working with DUALSHIELD and to ensure optimum quality, we recommend taking a look at our installation guidelines and our installation protocol. These guides will help you step by step to ensure professional implementation.

Maximize the protection of your designs and learn more about DUALSHIELD

Written by Sikla UK Oceania

Comments