By Harry Starke on 09 November 2020

The installation of cold-water pipes in building services projects can be a headache. Is this a challenge that you often face? Then you probably know the requirements of this kind of pipe installation. Keep reading this and find out all about a cold water pipe clamp that ticks all the boxes and surely will make your life easier.

Cold-Water Pipes Installation: why is this an issue?

The issue to be addressed is condense water on the pipe surface when the medium (cold water) temperature is expected to be lower than the usual ambient (room) temperature. Installing as normal, i.e. by using a lined or unlined pipe clamp that will later disappear under the insulation, leads, sooner or later, to corrosion that can affect the threaded rods, jeopardising the sustainability of the pipe supports.

Addressing the above technically correct means that the pipe must be insulated first, the pipe clamps fixed around the insulation, not around the pipe itself. The obvious problem with this approach is the lack of clamping resistance: tightening the pipe clamp’s flange screws with the usual torque leads to squeezing the insulation material. Not using the required torque leaves, on the other hand, the clamps prone to falling apart in the long term.

The experienced chilled water pipe installer knows all the above and has been using phenolic, polyurethane or wooden blocks as a denser insulation material where there are pipe clamps located. In NZ our customers used to use a wood-rubber combination that they call “the crocodile”.

All of these provide for the best of both worlds: there is continuous insulation sealing the condense water but also enough resistance to allow pipe clamps to be fully tightened.

However, this type of pipe installation combines technical requirements that seem to contradict one another but also nuisances that slow down the installation process:

- Insulation block plus pipe clamp means two components instead of one, in fact 3 instead of 1 because the insulation block can only be installed in 2 parts

- The installation of a support block and a pipe clamp requires ideally 3 hands, but a worker has just two

- The block must be made very accurately to leave no gap when installed, meaning there is one block for one exact pipe OD, without the flexibility of a size range

- Nevertheless, to ensure the block seals as reliably as the rest of the pipe insulation, a sealant should be applied both at the core and where the two halves meet, slowing down the process further

- In order to have acceptable thermal conductivity also where the block is located, the insulation pipe support has a limited load capacity, far lower than the pipe clamp

- As a result support distances (span) must be reduced for large diameter pipe, adding costs and installation time.

The Solution? Chilled Water Pipe Clamp SKS TOP 2C

|

|

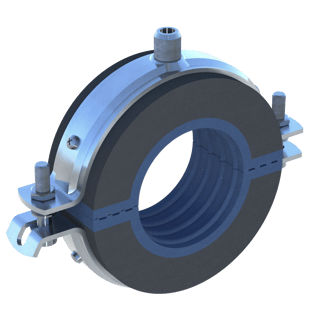

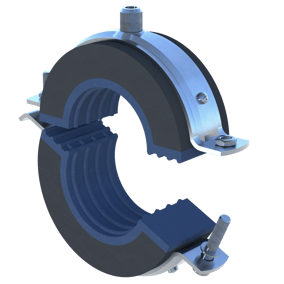

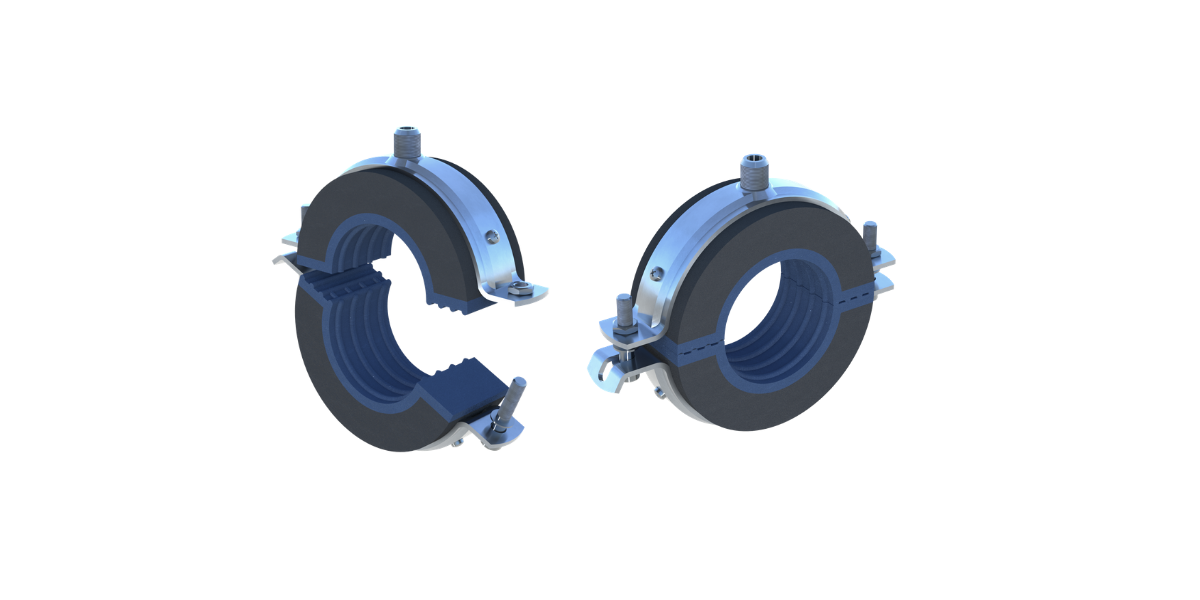

Here you have the features of the Chilled Water Pipe Clamp SKS TOP 2C:

- Polyurethan (PUR) block of high density (250 kg/m3 ) leading to high compression strength 0.7 N/mm2(for static loads)

- Stabil D3G pipe clamp pre-fixed to the PUR block with screws allowing installation in one piece

- Performing from -50°C up to +110°C whilst maintaining a high level of thermal conductivity at chilled water temperatures

- The blue elastomer layer adapts to different OD’s whilst blocking condense water without the need for a sealant

- Multi thread connection that can be combined with SIKLA adaptors up to 1” for solid wall-, floor or ceiling connections

Cutting the long story short:

Wouldn’t it be nice having a super pipe clamp that ticks all those boxes but can be used as quickly as a normal pipe clamp?

e.g. being delivered in one piece, covering a range of pipe OD’s per clamp, strong enough to take the load of the full pipe span and requiring no additional sealant?

The answer is:

this product has been around for a while: it is the water pipe clamp SKS TOP 2C from Sikla.

Having exported the product to distributors in Australia and NZ for nearly 10 years, the demand has increased since SIKLA Oceania opened its doors in 2019 and we have therefore decided to stock this range in Canning Vale, WA in 2021!

How interesting is this for you?

Would you need further details to start working with it? Let us know by contacting our team!

Comments