By Nigel Thompson on 24 January 2022

Steel corrosion protection is a topic often brought into discussion and detailed clarifications are frequently requested. In this article, we have created a PDF matrix where you can easily understand the ideal coating to allow corrosion protection in your project's steel structures.

Defining the information to effectively select a coating solution and achieve corrosion protection

As stated before besides any other specific project requirements, it is crucial for you to have defined:

- the structure's required lifespan

- the external conditions to which your steel structure will be exposed

Platform of an oil terminal, where Sikla siFramo 80 frames were exposed to the high salinity in a coastal area (Pacific Ocean; New Zealand)

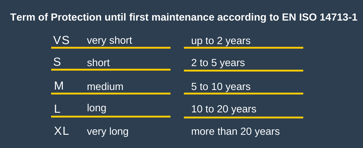

Why do the external conditions matter? If we refer to the established corrosivity categories, these combine a range from C1 – C5X, and are measured by the coating performance in an appropriate corrosion environment.

Taking the UK example, the norm for installation indoors would be C1-C3 and once construction is completed the product is not likely to be exposed to weathering. Anything outdoors would then be exposed to other elements, and therefore a C4+ would be recommended.

In summary...

- An appropriate HCP (High Corrosion Protection) finish is applied to be compliant with the required corrosivity class.

- The coating finish type is compliant to a corrosivity class, therefore defined by how long it would need to withstand the installation environment.

So what to check next?

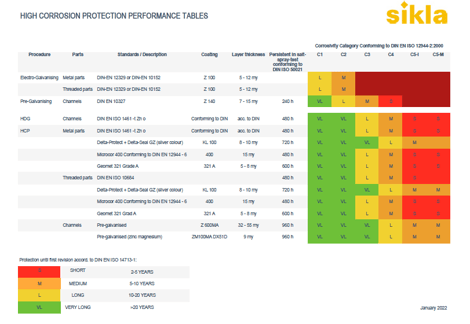

Combining all this information and deciding on the ideal type of coating can lead the planning teams to confusion and doubts. For this reason, we combined in a PDF matrix the relevant elements, delivering a comparison between the different coating approaches.

Download it now and check what is included:

- Shows you the coating options

- Categorises the components to be coated

- Mentions the quality standards which the coating process conforms with

- Informs about the coating thickness that each method will bring to the steel parts

- Refers to the hours in salt-spray-test

- Informs about the corrosivity category and the approx. years of protection

Is this information useful for you and your team?

Should you require additional details or a dedicated presentation and discussion about the topic, please let us know!

Comments