By Peter Walkden on 12 February 2024

siklaproof means Safe Planning.

Because we plan with siklaproof in mind from the beginning, our customers can rely on a secure solution at the end. Sikla can support you at every stage of the project. Read more about Sikla Oceania’s involvement in the Covalent Lithium refinery project here.

Covalent Lithium is striving to deliver clean energy on a large scale. Globally there is an increased demand for battery-grade materials in which Lithium Hydroxide (LiOH) plays an important role. Covalent is constructing a Mine and Concentrator 400km East of Perth and a Refinery 35km South of Perth in the industrial district of Kwinana.

Once completed (2025), the project will produce 50,000 tonnes of battery-grade LiOH per year.

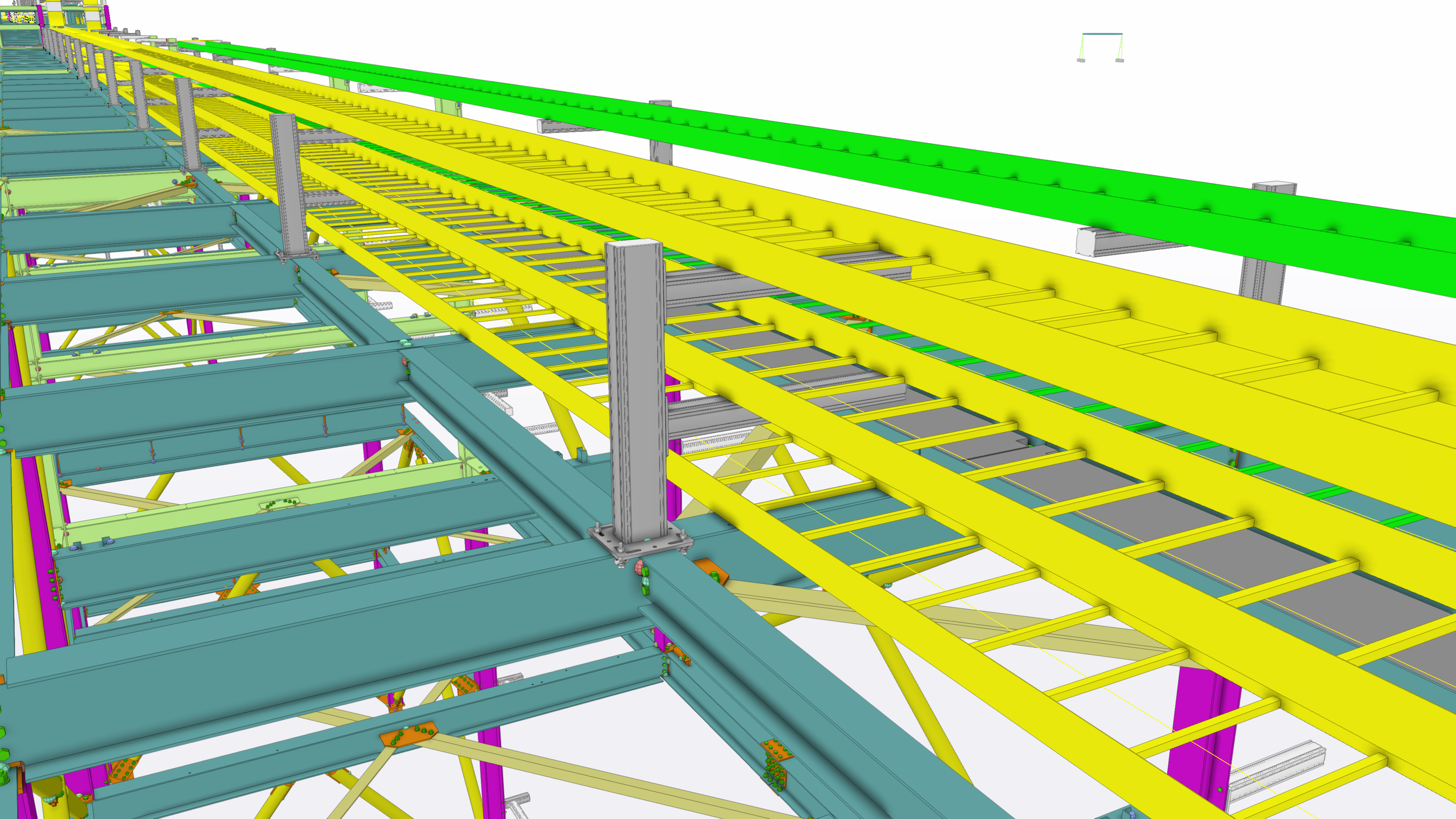

Detailed view of the model

Sikla Oceania engaged with Covalent in the early stages of the refinery project to provide engineering and construction modelling of modular piping and HV cable ladder supports. Over 250 tonnes of siFramo material was cut and prefabricated in our Canning Vale warehouse to create secondary steel support frames. Delivery was made directly to the site. During the project, Sikla had direct involvement with the SMP (Structural Mechanical Piping) contractor in the procurement of materials.

Bespoke siklaproof planning services

For this project, Sikla supports for the general steel design were in TEKLA. Thus, the design of supports preceded the completion of pipe and cable containment detailing.

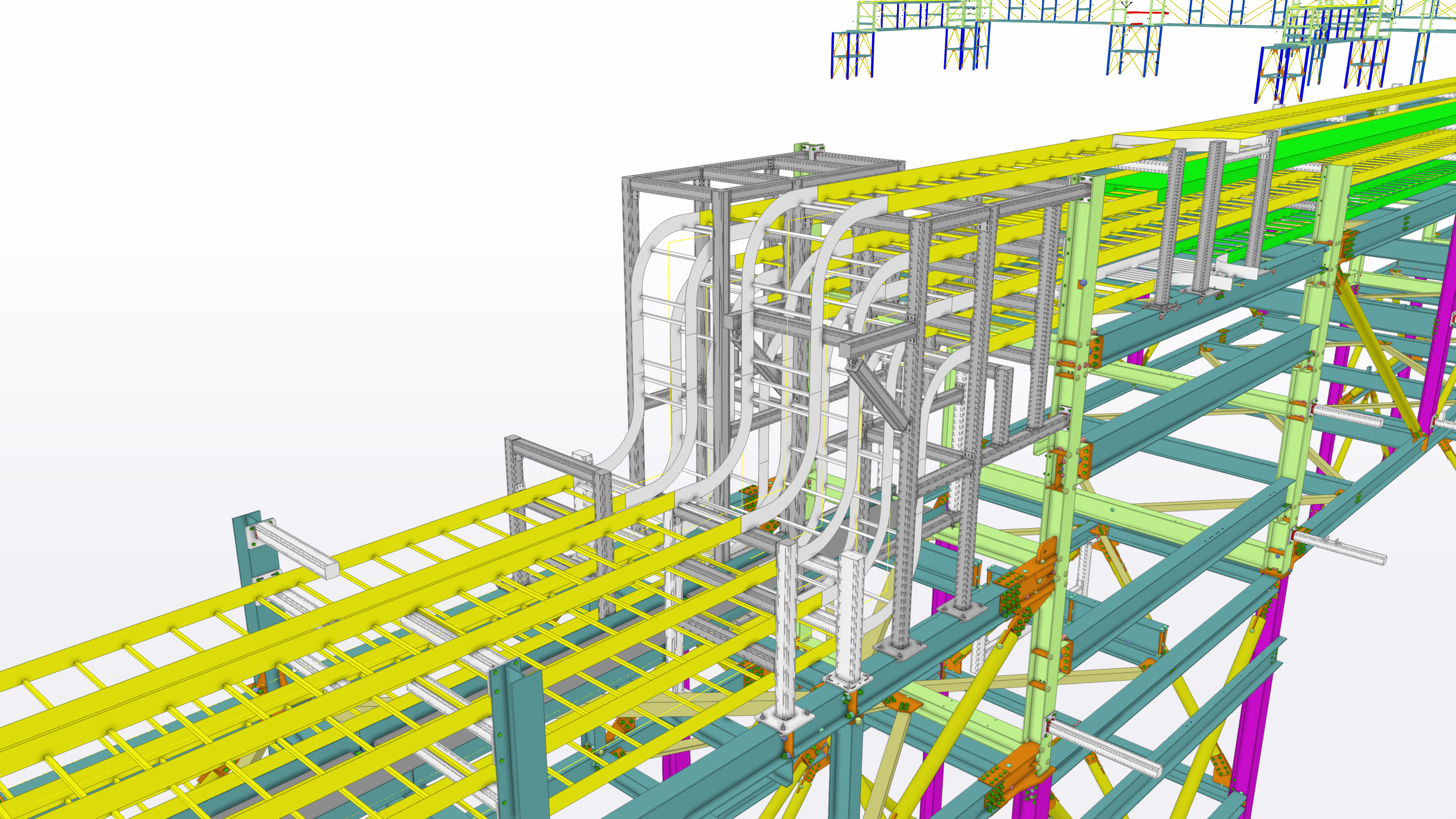

During the design stage, Sikla Oceania provided engineering and construction modelling of supports, to integrate with the client’s engineer. Working on a 2 milestone design workflow, models were integrated into Navisworks and Trimble Connect to coordinate within the federated model, perform clash detection and revision management.

Extract of the overall model

Using Aveva’s iConstruct software, Sikla has successfully supplied data-rich models to the client and SMP contractor with all the vital information to execute the project efficiently. This included material tracking, order process and cost control.

As a part of the procurement and fabrication of material, Sikla was required to produce MTOs (Material Take Off) and assembly drawings. Over 7000 prefabricated supports were supplied to the SMP contractor for installation. The majority of supports designed for the project used our MS 5P Assembly Set. This Assembly Set requires no hot work to assemble therefore is quick and simple to install, allowing the ability to adjust onsite to variations in construction tolerances and design changes.

Clamped assembly with the MS 5P Assembly Set

The supports were supplied fully palletised with corresponding pallet overviews and weights in line with construction work packs and site requirements.

Ready-to-deliver pre-assembled brackets in Canning Vale

“Besides the inherent versatility, using the Sikla SiFramo system allowed the design team to start structural detailing and fabrication before substantial completion of design and routing of piping and electrical services. Sikla supported the effort as part of the design team and performed admirably for their first significant foray into such an undertaking. The support we received on this project is commendable and the system is living up to all expectations.”

DAVID BRYDEN – LEAD STRUCTURAL ENGINEER (COVALENT)

The Project in Figures

- Over 7,000 supports

- Over 250 tonnes of material

- Implementation by Sikla UK (Planning) and Sikla Oceania (Prefabrication and Delivery)

Comments