By Harry Starke on 06 January 2021

The characteristics of the siFramo modular steel system make it necessarily a more obvious solution in chemical and pharmaceutical projects, compared to the Oil & Gas industry. Corrosivity requirements are more favourable to a product that comes hot dipped galvanised as standard, most pipe dimensions are small to medium and a big part of the mechanical systems is installed inside buildings, making siFramo just the right dimension to cover most of the pipe racking demands.

In Oil & Gas on the other hand conditions are rough, dimensions of pipework may be too large to make siFramo an appropriately looking structure and piping systems are usually to be found on, or inside, ‘pipe bridges’ whose heights, widths and lengths are way beyond the capacities of our steelwork product.

Somewhere between these two project types sits the petrochemical industry which, put simply, is chemical processing based on oil or gas, e.g. petroleum.

Over the 15 years of siFramo’s usage in those industries it was the latter which opened the door to some interesting niche applications in Oil & Gas projects which might otherwise never have been recognised.

Pipework in O&G may be predominantly outdoors, conditions that siFramo is designed for – rainwater cannot be trapped inside

Pipework in O&G may be predominantly outdoors, conditions that siFramo is designed for – rainwater cannot be trapped inside

In fact, siFramo is quite a useful product for both pipework and electrical installations in Oil and Gas projects, even offshore installations on oil rigs. To understand why this is, a common misunderstanding needs clarification:

siFramo, as standard, is an outdoor product!

The way siFramo has been designed, an installed frame will dry quickly on its own after occasional exposure to water, whether rain or a wave of seawater. In previous blogs it has been written about the structural benefits of corrugation and hole positions but, it is equally important to know that the geometric design of both the siFramo sections and its connection elements, eliminate the potential for water getting trapped. Furthermore:

- Hot-dipped-galvanisation is an outdoor coating meeting C4 requirements. The fact that the product is not offered with an inferior coating for indoors has its economics in mass production, i.e. the production and maintenance costs of an additional product line are considered higher than the cost benefits from offering cheaper coating for indoors applications.

- Associated Small Parts – for example form lock screws do not only offer level C4 protection too, but they are also compatible with C5 coating technologies that larger parts are not,

Which structures benefit from siFramo in Oil & Gas Projects?

Being aware of the above, the door is generally open to considering this modular steel system for a range of applications in Oil & Gas projects.

Typical areas where the product yields benefits are:

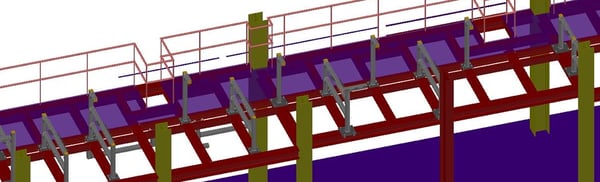

- Pipe bridge “fit out”, the integration of additional pipes into existing terminal infrastructure or the sub-structure design inside traditional steel frames of large structural steel dimension

- All high voltage electrical services – without ifs and buts

- Short-lived or temporary structures, for example a new drilling campaign of just 2 or 4 years often does not require a C5 coating because these corrosivity categories are based on duration in decades, not just years

- Permanent structures with either weight restrictions or flexibility requirements may justify the consideration of siFramo in a premium duplex coating that meets C5 requirements

- Other secondary steel structures, for example smaller access walkways, gantries, and industrial stairs, can be easily installed without hot works or drilling into existing structures

Apart from the generic benefits of flexibility and weight saving, which apply in all project types, there is one reason outstanding within existing oil & gas infrastructure: no need for drilling and welding. In some situations, this may save so much money, that the bottom line of a modular versus traditional steel comparison is being dwarfed: when an otherwise necessary shutdown can be avoided.

Surprisingly, standard coating can be enough in an aggressive offshore environment if the drilling campaign is just over a short period. Alternatively, the product can be offered with an approved duplex coating.

CAD Design Integration

An aspect more important than the product system itself, is its ease to get integrated into the CAD design process. Fortunately, plant software used in the oil & gas industry is the same as in other heavy industries that SIKLA and siFramo are more frequently used in.

Generally, Sikla has the raw data available to develop plug-in solutions for even the most peculiar modelling systems. However for the following software we are able to offer matured applications that will improve the modelling and drafting process of support structures significantly, compared to designing traditional steel structures:

- AutoDesk - Plant 3D

- Aveva - PDMS/E3D

- Intergraph - PDS/SmartPlant 3D

Our plugins for the above enable the smooth integration of sub-support structures into piping infrastructure dominated by traditional steel. Moreover, the user can choose from a variety of primary piping supports, such as pipe shoes, pipe hangers and U-Bolts that are compatible with both the historic or traditional steel supports and the modular siFramo system.

New users do not require detailed knowledge of the system’s component philosophy but can focus on designing the required goal posts, L – or T-stands with the 4 available section sizes. Connection points are auto-generated.

The main structures in bigger projects remain traditional steel but siFramo (above grey) is an ideal solution to address connection details.

Additional Benefits in Maintenance Access

In O&G it is also important to think of siFramo as a solution outside its primary purpose. As the only EN1090 / CE marked system of its kind on the market, the product has gained popularity as an instant solution for the design and erection of access platforms, walkways, and industrial stairs. Over the years, connection solutions for all types of grating, kick plates, stairs and hand rails have been found and are partly available withing the standard range of products. Both in the UK and in Australia we are able to offer this as a turnkey solution, without the need to co-ordinate a Sikla frame design with another supplier’s grating or handrail.

Additional maintenance access required? siFramo offers an instant but lasting solution with dedicated handrail and grating connectors.

Summing it up:

The Oil & Gas industry whether new built or maintenance, is the sleeping giant among all heavy industries already using modular steel technology. The benefits of the system are more hidden than in power engineering, chemical or pharmaceutical projects but they nevertheless exist. The best litmus test for advantageousness is to observe whether clients return to a solution on their own and without fresh encouragement. With Oil & Gas not being the primary target of our marketing campaign, we are quite impressed how a number of applications of our products have found popularity both within onshore oil terminal compounds and as part of offshore drilling campaigns.

Are you interested in learning more about how SiFramo can benefit your next project? Contact our team now for further details!

Comments