By Sikla UK Oceania on 04 May 2020

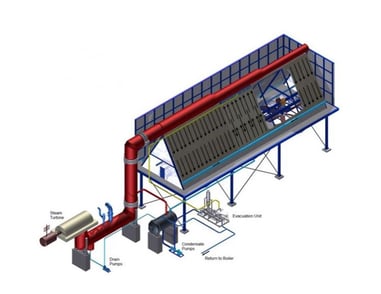

Greatmoor Farm , in Aylesbury, is an Energy-from-Waste(EfW) facility operating since 2016, which construction started in September 2013. Sikla was approached during this process (by the customer Clyde Bergemann GmbH) to supply the piping support system to an Air Cooled Condenser.

It was requested a quick response, with a solution capable of being easily adapted onsite to pipework alterations.

What was the challenge?

Typically, the contractor would have outsourced this scope of works to a steel fabricator in order to manufacture the supports in accordance with the drawings provided.

However, in the case of this installation, there were many unforeseen alterations needed on site as the pipe locations and direction changed frequently. Welded supports was not a possible solution, reason why the customer needed an alternative pipe supporting system.

Sikla was provided with a series of support drawings and installation isometrics for the installation of Air Cooled Condenser pipework.

Are you curious about the presented solution?

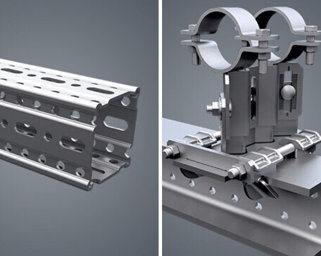

Sikla's design and technical office initial process was to determine which profile would be better suited based on the actions of forces and loads, detailed on the provided drawings.

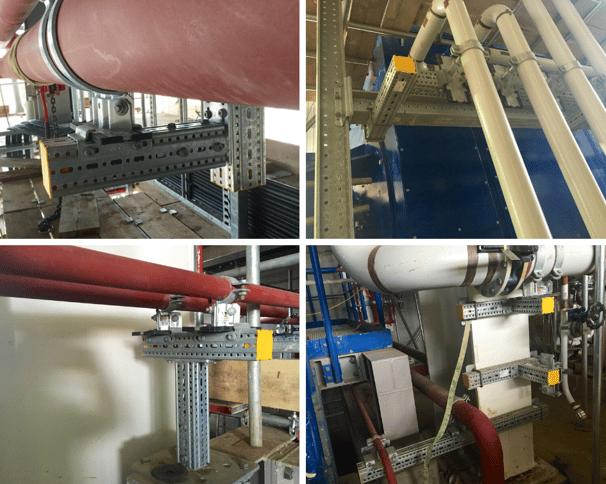

Once this analysis was completed, a range of siFramo 80 and 100 system parts were shipped to site along with Sikla’s Simotec pipe shoes, in order to install the Air Cooled Condenser pipework.

In several instances, the Framo system was used alongside Lisega Pipe Supports and spring hangers.

Want to see more photos of this project? Have a look here!

Here are the benefits achieved!

Remember: the main initial challenge was building a support system capable of being adapted to pipework changes onsite. siFramo’s easy adjustment and simple modification process allowed the supports to be built quickly on site, with minimal guidance, being easily assembled from a compact range of components.

Sikla's services and products, particularly the Framo modular steel framing system, were used for the first time by this customer. Therefore they got access and incorporated new concepts and solutions in their works and projects.

Testimonial

"The challenges we faced due to the installation of electrical containment and supporting bracketry meant we had to change several pipe routes. This was a perfect example of how the unexpected can be easily addressed with Framo modular steel framing system.

"Sikla attended site quickly in order to discuss the options available with the material we already had. Following a few technical calculations, we were good to make the intended modifications which were easy, straightforward with minimal installation time."

(Quality Management / Site Manager)

If you want to learn more about this kind of applications, join our next free webinar about Industrial Pipe Supports! Find out how the integration of Sikla’s high load bearing pipe shoes can benefit your project right from its early planning stages!

Written by Sikla UK Oceania

Comments