By Sikla UK Oceania on 27 January 2021

Waste management has been a hot topic in the last years and supplying for Energy-from-Waste (EfW) plants has been a major part of Sikla's performance over the past decade. You can actually relate to the fact that more than 20 power plants include solutions supplied by Sikla UK Oceania! Our modular pipe support systems are used in both water steam cycle and general piping elements, from design to pre-fabrication.

So how useful can this article be for you? It explores the benefits of Sikla's solutions which make it so appealing to be applied in this particular type of projects.

About Energy from Waste power plants

|

From the perspective of mechanical and electrical engineering, EfW plants are much like other types of power stations. Unlike larger power stations, they are often located in congested urban areas making the logistics of workers, site management and materials a challenge. In some cases, EfW plants are built close to remote landfill sites, locations that present significant but different issues. Many EPC (Engineering, Procurement and Construction) contractors have forged a powerful partnership with Sikla, by solving these together. |

|

|

Our enthusiasm for innovation, problem solving and transparency allows Sikla to collaborate with EPC contractors efficiently. |

Energy from Waste power plants |

Traditional approach to pipe supports vs modular solutions

Pipe supports have been designed and built of conventional welded steel for many decades. The requirement for siFramo came from deficiencies this traditional steelwork has. However, it does not mean welded I-beams are completely obsolete. They serve their purpose well under extremely high loads, long spans or as primary structures.

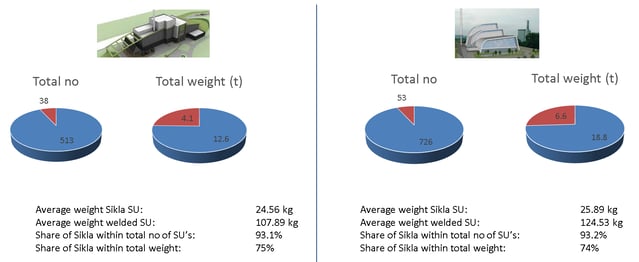

The following studies compare the weight saving benefits of our modular siFramo system on two independent Energy from Waste projects.

Weight saving case studies

(Get in touch if you would like to have more details on this topic)

By introducing the modular siFramo system Sikla provides a solution to the disadvantages welded supports have in terms of installation time, weight, manoeuvrability, availability and flexibility when it comes to design modifications.

|

siFramo time saving benefit, |

siFramo connection in 20 seconds |

Facing the challenges of modular steelwork implementation

Despite many benefits over conventional pipe supports, the rise of modularity faced some obstacles. Having overcome these obstacles, we have learnt that successful projects require the following:

- A detailed and thorough design process and planning. At Sikla we have developed software tools compatible with design management systems, which are being continuously improved.

- Off-site manufacturing. We have streamlined the prefabrication in our own workshops.

- Sikla offers products readily available from stock with a global distribution network (served by our units in the UK & Ireland, Australia and New Zealand and many other countries covering the whole world).

- Because modular steelwork is still a junior besides welded steel, Sikla offers support and training throughout the whole EPC cycle - from design stage through to installation.

Sikla service intertwined with EPC cycle

Here is just a taster of the many projects we've been part of...

As you can read from the start of this article, there are more than 20 completed projects which Sikla UK Oceania was part of (and a few others currently on our work desks!).

You can check the dedicated photo gallery here or easily relate to the projects listed below, as examples of some of the EfW plants that include Sikla's solutions:

- Rookery South EfW

- Istambul EfW

- Ferrybridge Multifuel 2

- Aircooled Condenser Pipe Supports at Greatmoor Farm (read more about it here)

- Kwinana Project (the first Energy Recovery Facility in Australia)

- Upcoming Dubai Resource Recovering Facility

Continuous improvement and its benefits

Since Sikla got involved with industrial projects, EPC cycles have significantly shortened. To be a valuable partner, we are developing our products, software tools and processes with every project.

| An integral part of our culture is regular communication with our clients. We plan together, we solve together, we grow together, by: | .jpg?width=525&name=2019.12.12%20-%20SIKLA%20(61).jpg) |

- Specifying priorities with our clients at the early stages of EPC cycle we are able to supply the right material at the right time, so progress on site can be uninterrupted.

- Supporting client’s designers and engineers with structural calculations and plausibility checks, which reduces design modifications at later stages of the project.

- Holding debrief discussions at the end of projects we gather valuable lessons learnt, which we eagerly implement in our next project.

The most valuable testimonials we receive from our clients are the opportunities to be involved in various disciplines of piping supports ranging from Water Steam Cycle (including Boiler and Turbine areas) to General Piping, also known as Balance of Plant, electrical supports and HVAC supports.

These are some the key aspects of our long and successful history with Energy from Waste projects.

If you work with us, you know this already. But if you are new to Sikla, contact us to meet our team!

Written by Sikla UK Oceania

Comments