By Sikla UK Oceania on 30 April 2021

Sikla is famously known for the welding-free modular framework. A small single-dimensional support or volumetric skid can be built, taken apart and rebuilt using a single type of FLS screw. And yet, various types of progressive welding methods are part of our manufacturing process to deliver the highly engineered product to your projects.

In this article, we will consider the benefits and disadvantages of pre-welded components in the siFramo range from a designer's perspective.

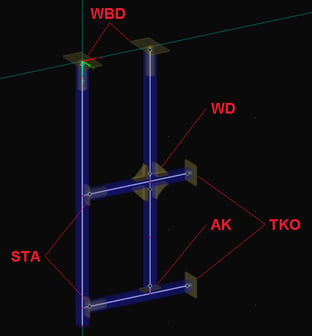

In a nutshell, there are two main types of connection – beam to beam connection and beam to primary structure connection. To create those connections, you can use either:

- Single pre-welded components which come in a form of beam section welded to base plate, e.g. TKO and AK

or - Two separate components which require connecting base plate and beam section using FLS Screws, e.g. STA and WBD.

Connecting siFramo steel beam sections

Three components known under abbreviations STA, WD and AK serve the same purpose – connecting siFramo beam sections. Yet, each of them has its advantages when designing frames:

| Cantilever Bracket AK | Corner Bracket WD | |

|

|

|

|

|

|

Connecting siFramo modular frames to primary structures

End connectors WBD and TKO connect siFramo modular frames to primary structures – concrete, primary steel or free-standing, and each has its own benefits:

| End Support WBD | Beam Bracket TKO |

|

|

|

|

|

Time to balance PROS & CONS: which components to choose?

In summary, requirements vary between flexibility, speed and strength and Sikla developed products to cover all of them. Designers should consider the following pros and cons of AK and TKO compared to their alternatives – STA and WBD:

| CONS | PROS |

|

|

We will be more than happy to assist you with your requirements or you can opt-in for our newsletter to stay on top of the thrilling trend of modularisation!

Written by Sikla UK Oceania

Comments