By Luke Totterdell on 01 December 2020

Last week’s article on secondary piping supports within power stations goes hand in hand with this week’s article on electrical supports. Last week we talked about how the unique challenges of power generation projects mean that SiFramo is a great solution for the support of mechanical services, particularly in areas of low repetition.

This week we will discuss electrical supports. Electrical services do not have the same dynamic loading conditions to consider as pipework/mechanical supports may have. It would therefore appear that electrical supports are simpler to design than their mechanical counter parts, and perhaps do not require the same level of attention.

We will go through two reasons as to why that might not be the case in power generation:

- The Complexity or Density of the Primary Structure & Adjacent Equipment

- Support Compatibility & Interfacing Options Adjacent Services

The Complexity or Density of the Primary Structure & Adjacent Equipment

As with all secondary supports, the complexity of the design is largely determined by the location of the service being supported relative to the primary structure. If a lack of primary structure is present then designs can quickly become complex.

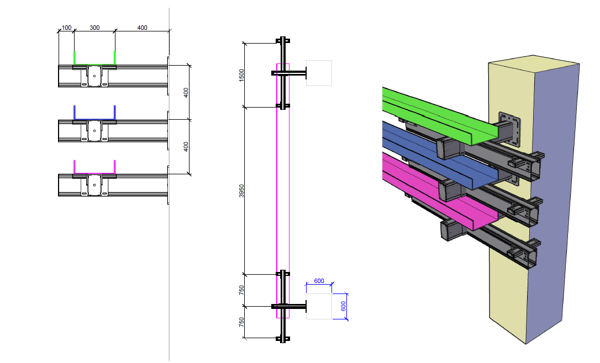

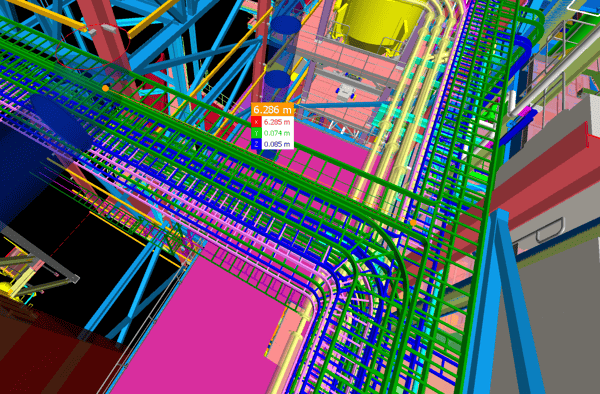

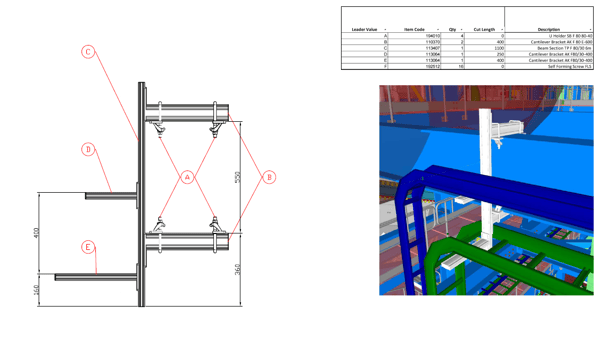

In instances like the image above, a large amount of electrical tray may be present without any primary structure to facilitate the supports that will be required. In situations such as this a competent secondary steelwork solution like SiFramo can have major advantages over traditional steelwork.

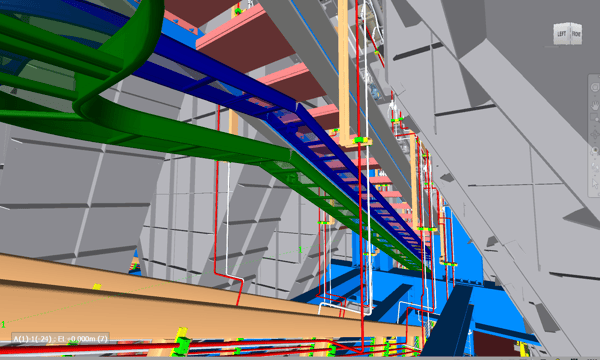

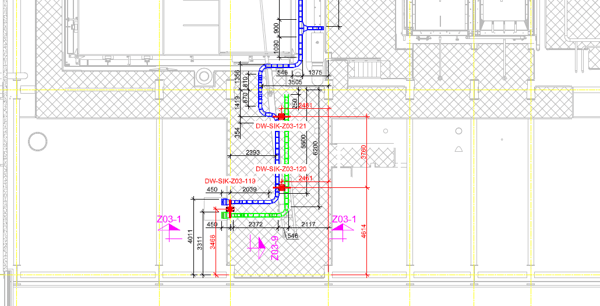

At the other end of the spectrum are instances such this second image, where cable tray routing is done through highly populated areas that are difficult to reach. Having the flexibility of a bolted system in these circumstances is beneficial when limited access and a constantly updating model may create situations where last-minute on-site adjustments are required.

Support Compatibility & Interfacing Options With Adjacent Services

A frequent issue on many projects is that mechanical and electrical departments are run by completely different teams, that often do not coordinate their supporting structures effectively. Traditionally mechanical services are given priority over electrical which leads to a lot of last-minute rerouting of cable trays. It can also result in positions where electrical and mechanical supports can become restrictive of one another and create clashes that could otherwise be avoided.

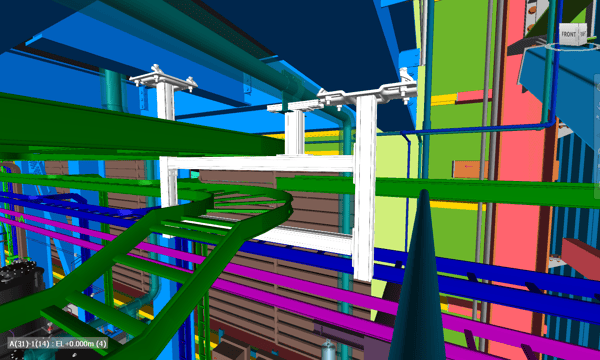

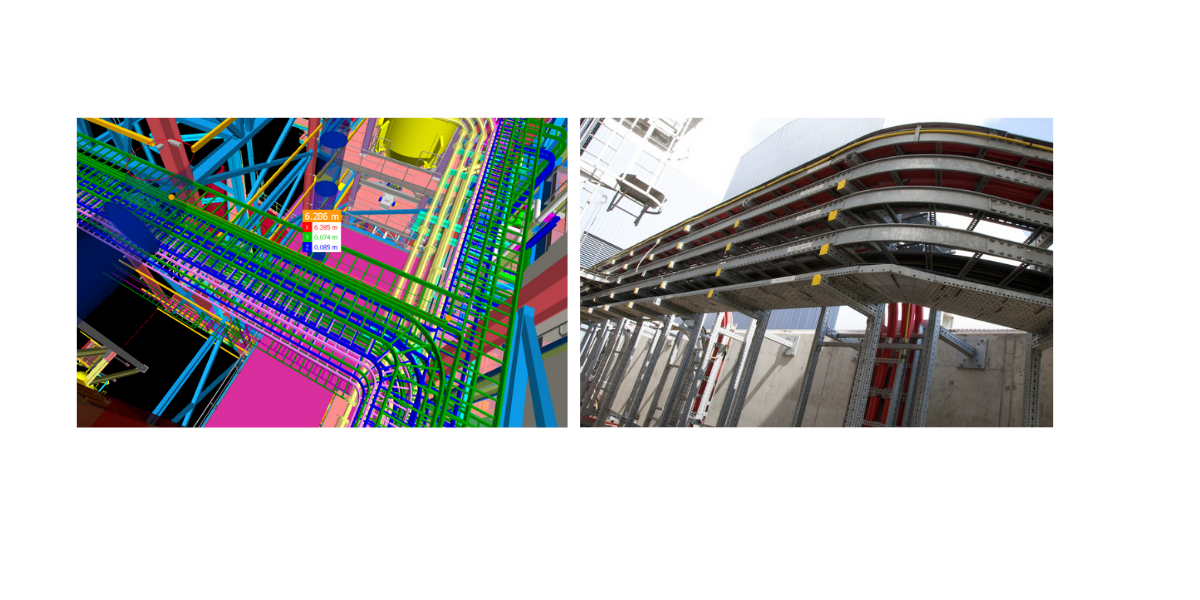

If the consideration of mechanical and electrical supports is undertaken at the same time it is possible to approach the supporting of these differing disciplines in a far more constructive way. Sikla has been able to achieve this by:

- Using the full range of design tools available. Being able to model supports for both disciplines whether they be independent or combined, allowing the client detailed review of support positions.

- Making the most of our modular siFramo system. Using the system's full range of flexibility to enable the effective support and interfacing of both disciplines upon the same structure.

- Communicating effectively with our clients. Having clear and concise discussions on how best to approach the design work at an early stage, as well as in depth reviews as the design evolves and becomes more fleshed out.

Using SiFramo in your next power generation project.

Whether the design of both electrical and mechanical is looked at from the beginning, or they are considered separately, using the SiFramo system allows the client to create supports that can be easily modified, and added too, to effectively cater to all situations.

Power generation projects create an ideal set of circumstances for the use of the Sikla SiFramo system. With low repetition in supporting structures and a high density of both mechanical and electrical services, the benefits to choosing a single system approach are there on a both a technical and commercial basis.

By choosing to use the SiFramo range this single system approach would be light-weight, easy to modify and simple to construct.

If you are interested in learning more about the system contact our team for further details.

Comments