By Sikla UK Oceania on 24 July 2020

At the heart of our Simotec product range, is a versatile solution that supports the numerous process & service piping that runs throughout a structure. Find out how the integration of Sikla’s Pipe shoes can benefit your project right from its early planning stages.

At what stages of building design are pipe supports planned?

During the preliminary phases of engineering, the pipe layout that runs through a building or plant is established early on. With a range of different services & processes required for operation, many of these involve the movement of substances from one location to another via piping..png?width=300&name=MicrosoftTeams-image%20(1).png) It is here that pipe bridges (or pipe racks) are necessary for the routing & arrangement of these pipes. They are designed specifically for support in locations where adequate structure is not available.

It is here that pipe bridges (or pipe racks) are necessary for the routing & arrangement of these pipes. They are designed specifically for support in locations where adequate structure is not available.

As a multi-levelled, civil structure - Groups of pipes are fed through systematically & placed horizontally at certain elevations.

Besides the need of a simple & economical arrangement, other factors must be taken into account when considering how the pipes are supported within the structure.

Design considerations & Challenges

With the transfer of: air, water, steam, condensate and nitrogen, the parameters surrounding these substances dictate the placement of the pipes that contain them. A pipe support is a designed element that transfers the load of a pipe to the supporting structures.

A key issue in every piping run, is pipe displacement (or movement), generated during operation as a result from a change in temperature or load, whether it is within the pipeline or in the external environment. If this element is unaccounted for, the system is likely to deteriorate quicker or fail, costing additional time and money on retrofitting & repairs. (Read more here about Piping Thermal Expansion)

Furthermore, as manufacturers of civil structures prioritise efficient on site assembly over design tolerances, discrepancies can often be found across the span of traditional welded steel frames.

Along with the higher tolerance required for pipework and the need of supports at different locations on varying pipe sizes, the height of pipe supports will be inconsistent across the length of the beam.

What is our Solution?

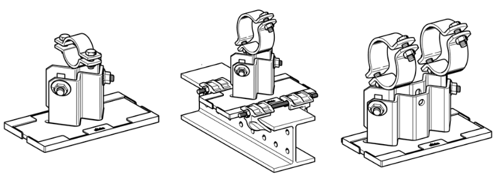

The sliding support forms the base of the unit and with the help of an additional accessory the shoe can be upgraded to become a fixed or guided support dependant on the application.

- A guided support: Holds the weight of the pipe whilst restricting movement in up to two dimensions.

- An anchor support: Bears the weight of the pipe, side and thrust loads whilst completely restricting movement in all three dimensions

One of the key benefits is in its ability to adapt to the discrepancies mentioned above and allow for fine adjustments on-site, all Pipe shoes in our Simotec range are height adjustable of up to 50mm as standard. This eliminates any tolerancing issues & inconsistencies that are difficult & costly to correct.

Height adjustable Simotec Pipe Shoes

Offering sizes from DN15 – DN600, these components are pre-assembled, available off the shelf, hot-dipped galvanised as standard & easy to install without the need of specialists or welders.

Our products are LGA & MPA certified, tested extensively to provide the best possible reliability and safety..png?width=208&name=MicrosoftTeams-image%20(2).png)

Lastly, aside from the ability to connect to conventional I-beams, these Pipe shoes are fully compatible with the rest of our modular steel work. Please refer to our siFramo modular steel system for more information.

.png?width=505&name=MicrosoftTeams-image%20(8).png)

Do you need further guidance about how to apply these products in your project?

Sikla design engineers will join you during the kick-off phase and assist your design team, implementing both modular steel systems and pipe shoes into the piping design process.

Contact our team now and join our next free webinar about Industrial Pipe Supports!

Written by Sikla UK Oceania

.png)

Comments