By Sikla UK Oceania on 09 February 2021

Do you have doubts and questions about Modular Pipe Support Systems? So what about having a quick and practical list of the most frequent questions that are often addressed to our team?

You can now find the answer to some of these questions by easily reading the next paragraphs, which we hope to be useful for you and your planning team!

1. Components' Details

3. System's Performance

4. Applications

5. Design & Prefabrication Services

Height Adjustable Simotec Pipe Shoes

Further on, should you require more details about these solutions, sign up now to attend our next webinar fully dedicated to it.

1. Range & Components' Details

|

|

Q: What is the biggest DN of Sikla pipe shoes?

A: It is DN600, LD type and these are off-the-shelf as the rest of the standard range. However, if you need pipe shoes that are above this diameter, we can also have a look at its specification and arrange customized manufacturing.

Q: Are these items available in stainless steel?

A: Yes, there is the option of providing stainless steel primary supports and other components. However, we would recommend to discuss requirements in more detail to determine whether an investment into high grade material is the most appropriate to your project or if it can be avoided to reduce your cost.

Q: What is the plastic component made from and can it be removed? What purpose is it for?

A: Each shoe comes supplied with a removable slide plate which is made of glass reinforced nylon (reinforced glass fibre). This allows to reduce the friction coefficient in sliding and guided supports.

2. Performance

Sliding Supports and Thermal Expansion

Q: Do these pipes shoes have a maximum temperature limit?

A: Yes, it's determined by the mechanical properties of the material to 300 deg.C. Designers need to be mindful of the temperature correction factor, which is available in our technical guidelines. For temp above 300 deg. C, we can manufacture pipe shoes from for example 16Mo3 or chrome-molybdenum alloys – up to 500 deg. C

Q: What is the maximum amount of allowable movement when supported by your 80mm beam?

A: Designers need to be caution of the pipe shoe slipping off the beam and there are a few approaches to prevent that. Piping stress engineers can calculate direction of the movement and amount of the movement. Based on that calculation, pipe shoes can be pre-set when installed so when pipe shoe moves in hot operating condition it does not slip-off the beam. Sikla pipe shoes have 250mm long base plates, which is usually sufficient, but we can also customise it to accommodate the movement of pipe

Q: What is the friction coefficient of the base and how does this affect thermal expansion?

A: The static friction coefficient is determined as 0.2, which we work with in our calculations.These are made of glass fibre reinforced Polyamide. It is standard for sliding and guided supports and removable for fixed points.

Q: Is the height adjustment incremental, and if so, what are these increments?

A: Yes, there is total height adjustability of 88.5 mm to 223.5 mm and the increments are of 2.5 mm.

Q: Does the adjustment allow for pipeline incline on steam and condensate systems?

A: Yes, there is enough tolerance and flexibility to allow the slope on the pipes.

Q: How is it applied seismic and heat effect on pipes together?

A: Once the piping stress analysis is done, we usually receive the results for each support position and work with this data to specify the correct pipe supports and design the right type of frame. [Get more details here about Seismic Proof Systems.]

3. Applications

Q: If we have for ex. DN 250 in size, what type of supports is best to use, LC-HV or LD-HV? How is this determined?

A: The LC type refers to the double clamp whereas the LD is the double clamp and double base plate type. What is the main difference: the LD type has higher loading capacity! Therefore, the decision about which one to apply would be determined based on loading in the given support position.

4. Design Tools

Q: Does Sikla share the design and planning tools access?

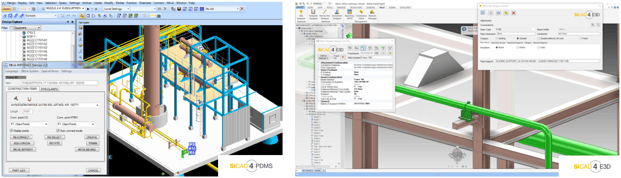

A: Yes, we share our plugins for the requested design tools, for example AVEVA, PDMS or E3D (the newly released). These plugins are live, constantly developed, so you will be receiving updates on a regular basis with all the latest improvements.

Our plugins are free of charge and we offer all the technical support to your design team once you start using it, allowing the start of the project to be as smooth as possible.

Any other doubts left?

The questions you've seen above and several others were raised in the several presentations about our Modular Pipe Supports solutions. If you want to learn more about the topic sign up to our next Industrial Pipe Supports Webinar and get the chance to directly talk with our Engineering team about this topic!

Written by Sikla UK Oceania

Comments