By Sikla UK Oceania on 07 December 2020

When presenting the siFramo modular steel system our team often faces some common - and quite interesting - questions. Maybe some of them represent your doubts and concerns too about this system. So why not sharing the answers to these doubts, right?

In this helpful FAQ page, you will find a list of frequently asked questions and our direct answer to it, organised in 5 practical categories:

1. Components' Details

2. Corrosion Protection & Coatings

3. System's Performance

4. Certifications & Testing

5. Design & Prefabrication Services

1. Components' Details

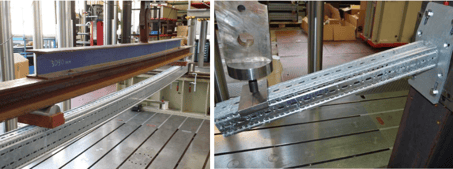

Q: What length are the sections produced?

A: The standard is 6m length, but we offer customised cutting service when requested.

Q: What is the weight per metre of the F80 and F100 sections?

A: siFramo F80 has approximatley 6 kg/meter and F100 around 10 kg/meter. The siFramo beams are up to 50% lighter than traditional steel of similar load carrying capacity, and in most instances, pieces can be carried and positioned by a single person. (Keep reading more here about siFramo's weight saving.)

Q: These components are connected with only one single type of screw?

A: Yes! With the siFramo system, only one type of screw is required for every connection (different profile dimensions and load ranges). Find here detailed information about Sikla Self-Forming Screw.

Q: Can the different profiles be used in conjunction with each other and if so do you need special adaptors?

A: Yes they can. The system is design in a way that you can always adapt it downwards. Therefore, if you build a base frame based on F100 or F100/160, you can use the available adaptors in the range which allow you to reduce to F80/80 or F80/30.

Q: Is there also the possibility of connecting siFramo with normal channels?

A: Yes, it is possible to connect Strut-Channel to the siFramo frame with specific adaptors.

Q: What is corrugated?

A: Corrugating is a metal folding technique that adds strength to the structure.

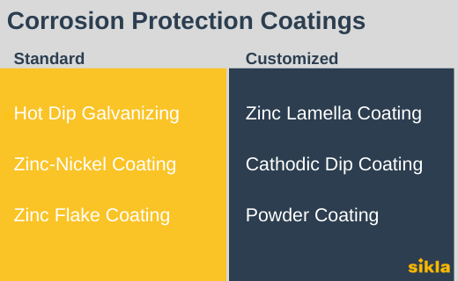

2. Corrosion Protection & Coatings

Q: Do we need to paint the frame after for protection?

A: All sections and components come already fully hot dipped galvanised.

Q: Can the SiFramo be painted any colour to suit architectural requirements?

A: Yes. We have experience with different powder coating techniques whether for cosmetic, esthetic or additional protection reasons.

Q: Do we have to treat the ends of the beam after cutting if it is galvanised?

A: Usually not due to the cathodic protection effect.

Q: Are stainless steel items available?

A: Yes, there is the option of providing stainless steel primary supports and other components (not the majority of the siFramo system components). However, the economical viability of it is most of the times questionable. Our experience is that in traditional steel applications where we use a secondary frame this would be, in many cases, a mild steel frame with C5 coating, instead of stainless steel. Stainless steel would then only be applicable to the pipe supports / pipe clamps.

So it might be worth questioning: does your project really need the whole frame from stainless steel? We would recommend to discuss requirements in more detail to determine whether an investment into high grade material is appropriate to your project.

Q: How much time can siFramo resist outside in normal conditions?

A: The standard product is hot dip galvanized, therefore sustaining C4 conditions (corrosivity category 4). For special outdoors applications, e.g. in coastal areas or aggressive atmosphere, there are higher demands than usual in terms of corrosion protection. These specific different coating systems are also possible to apply to the system (not being an off-the-shelf solution though).

(Find here a detailed explanation about Coating and Corrosion Protection on Steel Structures)

3. System's Performance

Q: As the steel is thin, how long can you guarantee the frames will last for?

A: This depends on the corrosivity class, i.e. the installation environment. Usually you should expect a lifetime of up to 40 years.

Q: What is the maximum safe working load?

A: This question doesn't have a direct answer as the working load capacity will depend on the section/frame being installed. Further explanations about Load Capacity is detailed here.

4. Certifications & Testing

Q: What is the norm EN1090-1?

A: EN1090 is the European norm for fabricated steel delivered to site. Our pre-fabrication has been EN-1090 accredited since 2016. We have production and quality control in place to provide you pre-assembled supports, in conformity with the European standard applied to structural metalwork.

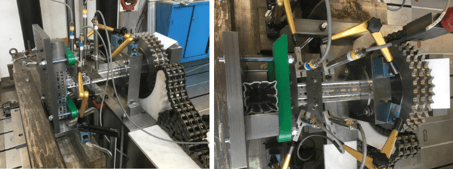

Q: Has there been any fire testing carried out on SiFramo?

A: Yes. Product test results were calculated and analysed by the Pipe Fastening Association (RAL) and by the Material Testing Institutes (MPA). This cooperation has enabled us at an early stage to calculate fastening designs under defined requirements, as well as conduct a scientific analysis of load and deformation values on specific components from fire tests. Read more about this topic here.

Q: Has any seismic test been done?

A: Yes, seismic tests have been made. Worth mentioning that the RSTAB structural software gives us the option to calculate the system for seismic loads (against EU and Australia/NZ standards). Access here our Seismic Design and Instalation Guidelines

Q: Is siFramo approved for use in Nuclear projects?

A: There is no general approval for nuclear projects. But we can say that siFramo will be possible to use depending on the project and within the zone of the nuclear plant where it would be applied. (The closer you get to the reactor the more approvals are required.)

4. Design & prefabrication Services

|

|

|

Q: Do you provide design services?

A: Yes, we support you with 2D / 3D detailed planning by using powerful software design tools from the SiCAD family. We have various BIM plugins and bespoke analysis software which support the planning and design process.

Q: Are all components included within the PDMS and E3D plugin?

A: Yes. The Sikla interface SiCAD4PDMS / E3D is available for PDMS or E3D from AVEVA.

Q: Is possible to pre-assembly typical frames?

A: Yes. If required, the system can be pre-assembled at Sikla’s premises by our team.

Was this useful for you?

Most of these questions were collected during our siFramo webinar sessions, but could be raised in any other context where the topic is discussed.

If these were your questions too, hopefully you've found this article useful (and why not sharing it with your team now?). In case you still have some different doubts about siFramo Modular Steel system, please feel free to reach us with your queries. Contact us now!

Written by Sikla UK Oceania

Comments