By Ross Smith on 15 February 2021

In our original blog series we detailed the key points of the siFramo modular steel framing system, presenting its applications and multiple benefits from a general, layman’s perspective. This week's article marks the start of a brand new series of blogs in which we will explore more specific siFramo applications, for the inquisitive (and soon to be experts) of you out there, who just love the product as much as we do.

Familiar (but not too familiar)

|

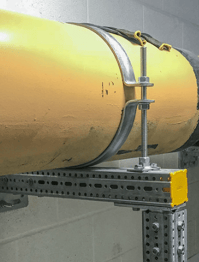

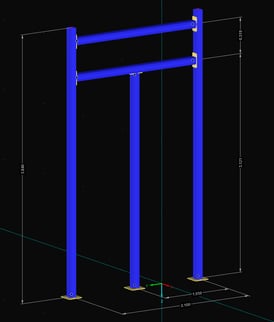

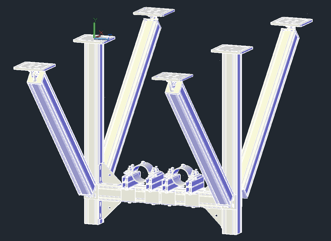

The aptly named and immediately recognisable siFramo ‘Goal Post’ arrangement, is our bread and butter, not only because of its impressive load bearing capabilities, but also because of its inherent adjustability. |

|

Millimetre Specific Adjustability

|

|

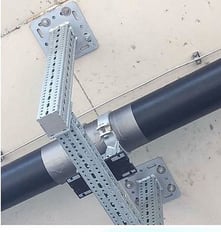

Case in point, two DN200 pipes running through a Waste Water Treatment Plant. Due to the varying chainage of the pipeline, a series of siFramo goal posts were used to support the pipe shoes at differing elevations across the site. Precise elevational adjustment was achieved here in two ways: firstly, from the Sikla adjustable pipe shoe and secondly, from the height adjustable siFramo crossbar, which allows for unrestricted and millimetre specific accuracy along the entire length of the vertical member. |

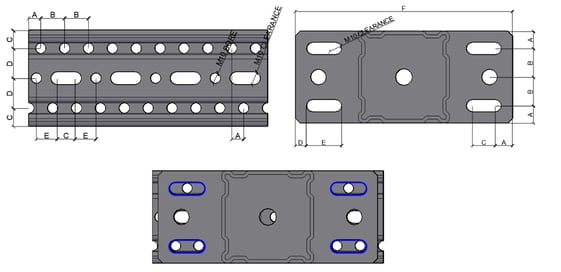

This level of crossbar adjustability remains present on all sides of the section and is achieved through the combination of the offset siFramo screw holes and the slotted baseplates, allowing at least 4 fixing positions for the FLS screws to always be located.

Impressive Load Bearing Capabilities

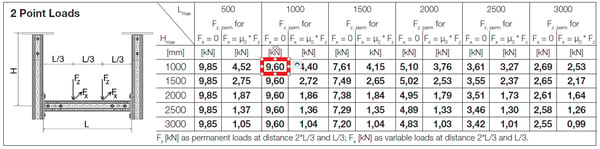

Though siFramo boasts a significant weight saving over a conventional steel equivalent, you may be surprised to discover that it also outperforms a traditional steel frame in a direct strength-to- weight-comparison.

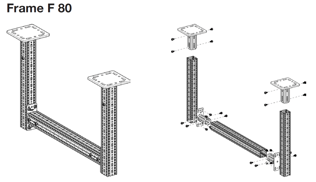

In the above example (two DN200 pipes ≈ 6.7kN of load) you can see from our installation guidelines that the F80 goal post (roughly H=1000mm, L=1000mm) supports an overall capacity just shy of 1 metric ton! Very impressive statistics (I am sure you will agree) from a frame weighing only 30kg!

|

|

Inverted (but still exerted)

|

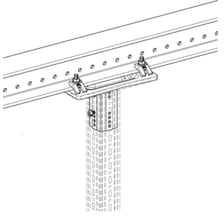

The inverted goal post, often referred to as a "trapeze bracket" (though completely suitable to swing from, we do not advise it), is another very common arrangement to see suspended from concrete ceilings or spanning horizontal I-beams. |

Just like its mirror image, there are two available fixing methods to secure the inverted goal post to your substructure:

|

Option 1 - Anchor bolts |

|

Option 2 - Beam Clamping Sets |

|

|

|

|

|

|

|

But what if we need it all flat?

When overhead clearance becomes tight (think accessway or maintenance corridor) we offer the STA-E type connection to create a flat top (or bottom) crossbar connection which is completely flush with the ends of the perpendicular uprights. Although this type of crossbar connection is more commonly used in trapeze bracket supports, it may also be specified when the entire length of the crossbar is needed to mount services or equipment. Alternatively, the STA-E type version of the goal post may be required simply when aesthetics take a greater precedence (“can we just keep it all flush?”).

|

|

Albeit very pleasing on the eye, the STA-E type crossbar was also designed to allow very low running services to be picked up and supported by the crossbar of a goal post when the backing plate of the standard STA end connection would otherwise protrude too far down the vertical to allow such a low connection.

|

|

Thinking outside the Goal Post

It is completely possible to orientate the STA end connection downwards, or perpendicular to the connecting surface, to create one continuous flat crossbar. This arrangement is particularly useful for sets of closely grouped pipes, where every millimeter of the supporting surface is required, or, when extension of the crossbar is needed to pick up overhanging services.

|

|

|

When spans are large and services are particularly heavy, the beautifully functional and square nature of our box section allows a third (or fourth, or fifth) central leg to be incorporated into the goal post. This can even be done after the frame has been erected, should, for example, site teams choose to take advantage of our easy-to-use system and pile on some unexpected additional services (!).

|

|

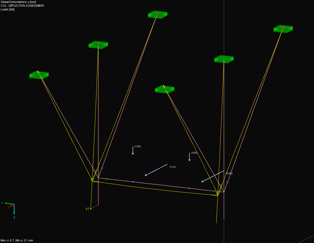

When faced with extremely high axial - ,or 3-dimensional loads, we offer braced goal post solutions which are engineered using our in-house structural analysis software. These bespoke frames can be integrated into client models from the early project planning stages on, and typically incorporate one or more of our integrated Fixed Point Solutions.

|

|

It is the adjustability and versatility of the siFramo box section which allows additional crossbars to be added up or down the entire length of the vertical member. We can integrate crossbars which reduce in profile size (due to our offset end connectors) and we can even integrate a channel / Unistrut system into the goalpost (by using our dedicated SA F80 channel connector). This is especially practical when the larger capacity of siFramo is not required to pick up lighter loads or smaller services, such as SB pipe and cable tray.

Where to go from here?

With the profile being square and having a connecting surface present on all four sides, a perpendicular connection can be supported from the goal post to pick up additional pipes running nearby in a separate axis or elevation.

Why not add in a second perpendicular leg? Sure, but then we are delving into the realms of 3-dimensional volumetric frames, which is a separate topic and one to be discussed in a separate blog (watch this space).

Key takeaways from this article

- High versatility, adjustability and strength

-

Numerous potential arrangements

-

Customisation to your requirements

Should you require additional details about this design in particular (or other siFramo possibilities), contact our team or sign up now for our CPD training!

Comments