By Jen Bradley on 15 June 2023

Sikla invented siFramo, a multipurpose modular steel support, more than 15 years ago. What made this system so significant at the time? One Screw Technology.

One Screw Technology describes the fact that only one kind of screw is needed to assemble a Sikla siFramo support frame. This screw provides our clients with many advantages during an installation stage of a project, known to many as the Self Forming Screw FLS.

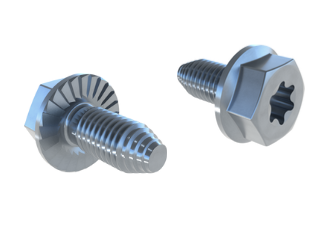

Introducing the Self Forming Screw FLS

The only screw required to assemble siFramo.

Sikla Self Forming Screw FLS

Using one type of screw to assemble, on or off-site, eliminates confusion about the materials needed to build a Sikla support system capable of supporting any weight.

The unique and innovative design of the self-forming screw is used to maximise all sides of the siFramo profile for connection points. Our technology allows customers to experience productivity in addition to saving time and money by reducing:

- The amount of extra material

- Overall waste

- The need for workers who can weld

- Shipping costs and carbon footprint by ordering from a single source

Features of the Self Forming FLS screw

The FLS screw is self forming which means it forms a strong thread inside the siFramo beam.

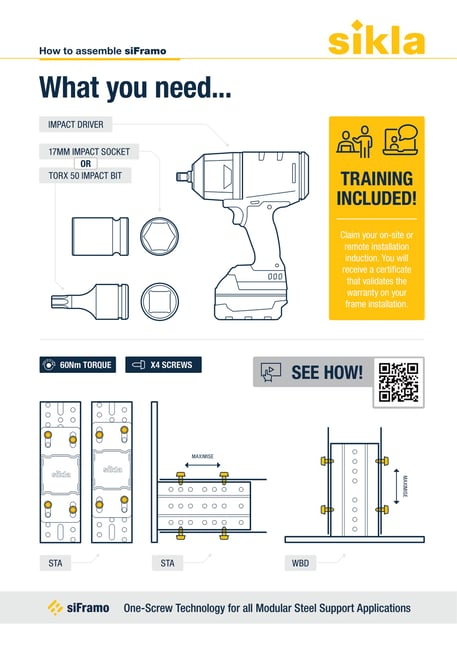

At Sikla, we prefer to use an impact driver to install the Self Forming FLS screw to achieve the required tightening torque of 60Nm.

Discover Sikla's recommended techniques for installing siFramo

When installed, the FLS screw creates an air-tight seal between the tread and steel inside the beam section. The air-tight seal is formed by re-shaping the steel and creating serrations to offer the following safety features:

- Zero play between the screw and hole preventing self-loosening

- Minimise vibration

- Prevent overtightening from the impact driver

Watch how the air-tight seal is formed in this video

The most impressive feature of the FLS screw is that you can adjust its position, making it higher or lower for example. The screw can be removed and re-used a maximum of 3 times, after that, the thread becomes too weak and you lose the safety features.

Check out how simple it is to adjust your siFramo beam:

Benefits of the FLS screw and siFramo

The siFramo system is renowned for being significantly lighter yet stronger than traditional steel beams. siFramo can be adapted to suit a variety of industries and is versatile to be used in a range of industries. What other advantages can the FLS screw and siFramo provide you?

- No need for hot works

Increase site productivity and reduce the cost of hiring skilled labourers with a hot works permit. With the correct training and an impact driver, anyone can assemble siFramo onsite

- No nuts, washers or back plates

Reduces the number of parts needed to assemble and therefore speeds up assembly and installation times

- Connections on all 4 sides of the beam

Connections can be made anywhere on the siFramo profile due to the pattern. The size of the screw means there will be no clashes and reduces waste

- Able to be Hot Dipped Galvanised

To prevent corrosion and increases the life span of the product

- Unlimited number of connections

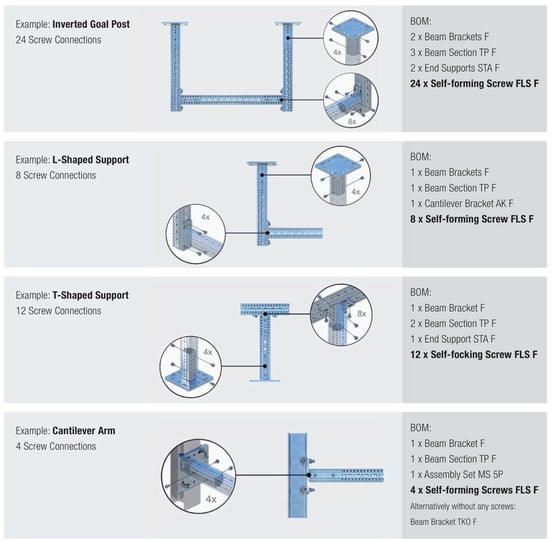

Create an Inverted Goal Post, L-Shaped Support, T-Shaped Support or Cantilever Arm

Do you need training or further guidance?

Sikla offers onsite or remote inductions in safely assembling and installing siFramo to validate your warranty. Get in touch with us today to find out how we can help.

Please note:

Hilti has recently launched a thread-forming screw under the product name "MT-TFB OC". This product is hard to distinguish from the "FLS-F" original Sikla screw and we would like to notify our customers that the Hilti screw is incompatible with our system. The use of the screw in conjunction with the Sikla system compromises the validity of published load data, declarations of performance and practical stability of installations. In the event of uncertainty on the supply source of thread-forming screws, please contact Sikla using the buttons above.

.jpg)

Written by Jen Bradley

Regional Marketing Coordinator for Sikla UK & Ireland, Oceania and USA

.png)

Comments