By Sikla UK Oceania on 23 March 2021

Introducing our most versatile component from the Sikla catalogue: Pivot Joints. What will you learn from this reading? What is and what are the types of pivot joints, which support types can be designed in retro-fit scenarios & finally 4 practical examples of pivot joints applied to real projects.

- What is a Pivot Joint?

- Types of Pivot Joints

- Support types in retrofit scenarios

- 4 Designed scenarios & examples of Pivot Joints used in projects

What is a Pivot Joint

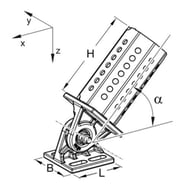

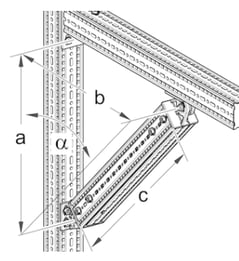

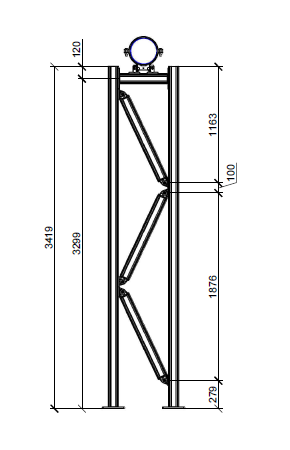

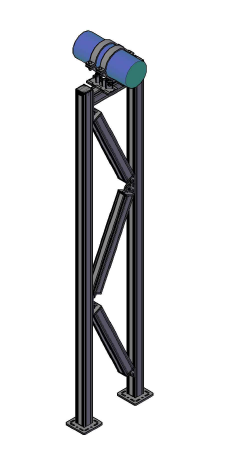

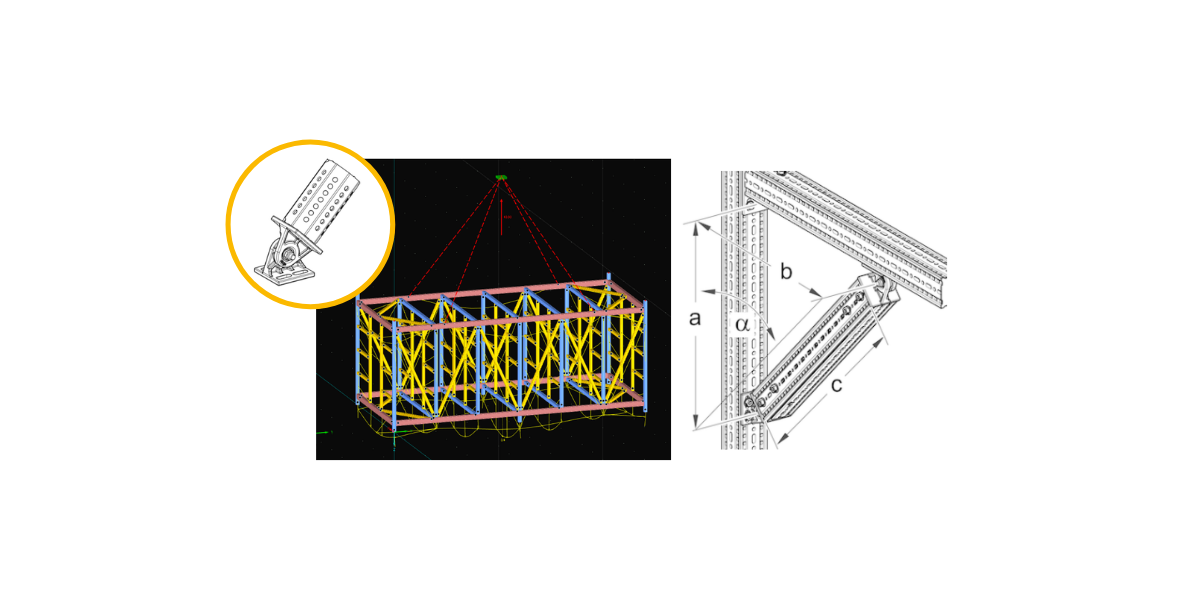

Lets examine what makes Pivot Joint so unique and sets it apart from the rest of the components. Pivot Joint component has a freely moveable joint that allows rotary movement around a single axis. This joint sits in the centre of the baseplate, which allows for turning of the attached coupling from side to side and achieve an angle range of 25 - 155 degree.

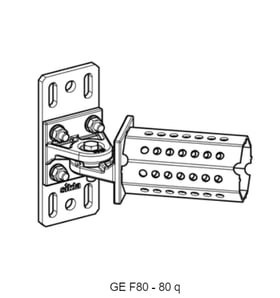

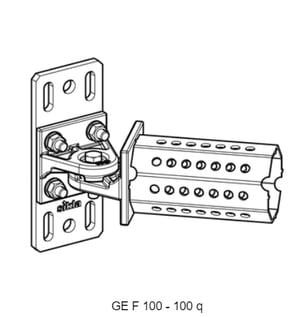

Attachment of Joint GE F 80 to Beam Section TP F 80 by means of 4 Self Forming Screws FLS F at the base plate. The support profile TP F 80 plugged onto the octagon is also attached by means of 4 Self Forming Screws, so 8 Self Forming Screws are necessary in total. After installation at the desired angle the screws have to be tightened with 40 Nm.

|

a = vertical length from centerline of joint to bottom of profile at connection b = horizontal length of cantilever from connection to centerline of joint |

Types of Pivot Joints

As you are probably aware, we have four standard siFramo sections that are widely used across different projects. They all vary in sizes and applications from using F80/30 profile for cable tray supports to using F100/160 in a riser structure.

Our pivot joints are designed to be compatible with every beam size. You will find a pivot joint for every type of profile, not only that but we also have pivot joint type which will accommodate for a drop in profile size. The best example of it is Pivot Joint GE F 100 – 80. The base plate is designed to be attached to the F100 profile, while the internal coupling connection is compatible with F80 profile. This characteristic proves to be particularly useful when pivot joints are used for bracing within the designed frame.

|

|

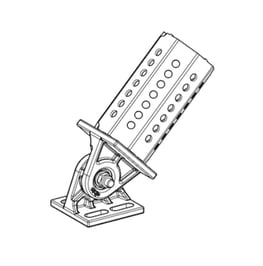

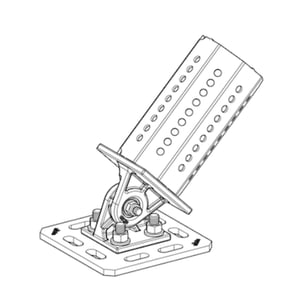

One of the best attributes of this component is that it can be used in different orientations.

|

|

One of the other alternatives we provide are Pivot Joints that come in a variety of base plate sizes. The size range covers I-beam flange width between 80mm to 310mm. They are compatible with our Assembly Set and can be clamped to primary steel. Or alternatively anchored directly to concrete. Which can be advantageous for retrofit use.

Support Types in Retro-fit Scenarios:

Firstly, let us examine how Pivot Joint can be used in a simple L-bracket assembly. In this instance the brace is positioned in the same plane as the frame itself. Majority of the time when the cantilever bracket is struggling to withstand the total weight of the supporting pipes a brace would be introduced as a solution. We would add an additional brace underneath the cantilever bracket to transfer some of the weight of the piping and reduce the deflection of the member.

|

|

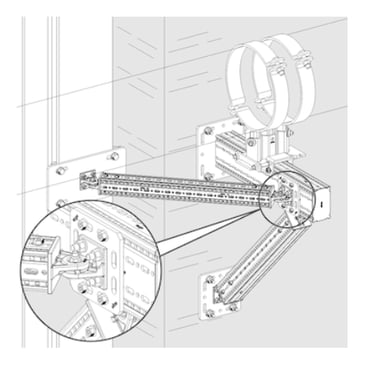

Another scenario in which the bracing could be used is represented by the frame below. As you can see the frame is braced back directly to the wall. This would reinforce the frame and resist dynamic forces. This is a perfect solution for high axial and lateral forces whether they are acting separately or combined.

Quite often when we are required to look at an anchor support for the pipes or a support solution for high axial forces. We would look at integrating some bracing into the Goalpost design to add additional rigidity to the frame. This way the axial forces would be counteracted by the bracing, as seen in the image below.

4 Designed scenarios & Examples of Pivot Joint use in projects:

1. Deflection

|

Often bracing would be used on site to reduce deflection. When a beam run has a long span or is not supported regularly, the beam would start to sag in the middle. This can be counteracted by connecting a brace to the supporting upright and spanning it to the underside of the crossbar. This would reduce deflection within the beam and provide additional structural integrity. |

|

2. Buckling

|

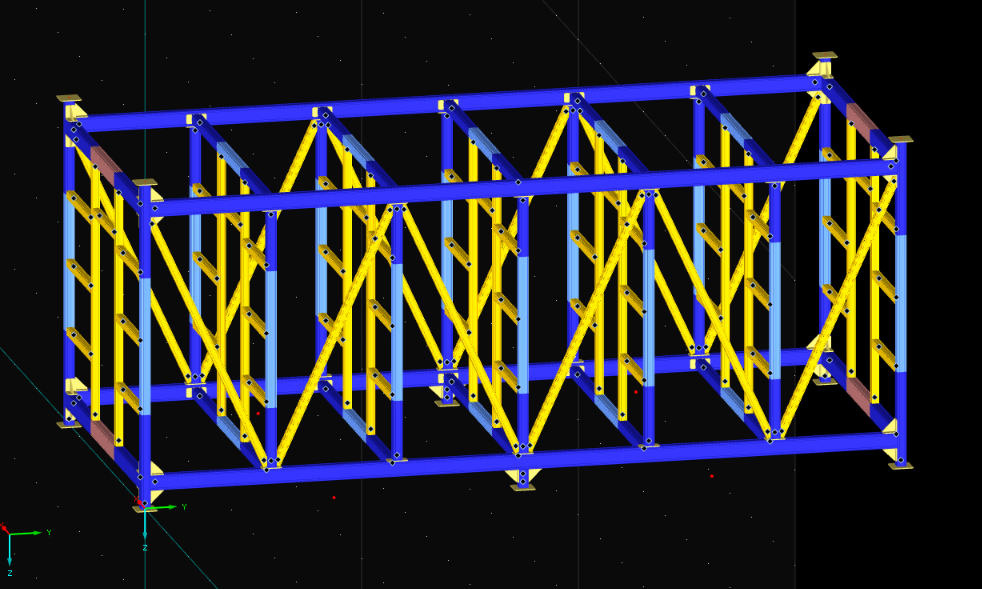

The use of the bracing is essential when it comes to reducing buckling of the frame. Cross bracing is used internally to add additional rigidity. This is especially the case with high level frames in instances where creating a volumetric design is not a viable option. The best part about the Pivot Joint component is that no matter how high the frame gets, we will always be able to adjust the angle to find a perfect bracing solution. Occasionally the support stability is so poor, that in this instance we would not only use one or even two cross braces, as it is quite common within the industry. We can use it multiple times as demonstrated in example below. |

|

|

3. Conditional Use

As you can imagine Sikla is involved in a variety of projects in different parts of the world. This being said, we are required to consider various weather conditions during our design process. In this type of scenarios, we are required to protect our structures from external forces. And prevent our frames from destructive effect of the forces such as wind and snow.

One of the important things to consider would be the Seismic activity of the area and likelihood of earthquakes. In all of these instances our pivot joint come in handy to reinforce the bracketry.

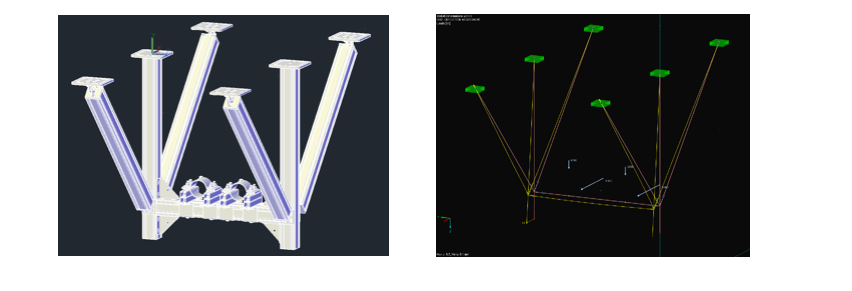

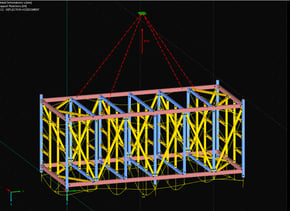

4. Lifting of the frame and Modular design

Often when it comes to lifting a module onto the roof of the building, we would use cross braces as a temporary solution to help with the rigidity of the structure and reduce deflection during the lift. These braces can be removed at a later stage once the module is secured into position.

|

|

How would you use it on your project?

It is visually appealing and aesthetically pleasing. It effortlessly brings a clean look to any steel structure.

"How would you use it on your project?"

Written by Sikla UK Oceania

Comments