By Sikla UK Oceania on 14 September 2021

Rookery South Energy Recovery Facility will process over 545,000 tonnes of non-recyclable waste, which will generate over 60 megawatts of electricity each year - enough to power over 112,500 houses!

We can proudly say that this project is one of the more than 20 Energy-from-Waste (EfW) plants in our portfolio! It challenged us to support design & engineering process, pre-assemble and deliver several skid frames and more than 6,000 height adjustable pipe supports (responding to Hitachi-Zosen Inova specifications).

Among many other projects, we find that the Rookery Energy Recovery Facility is an incredible example of how to successfully fulfil Offsite requirements & Sustainability with Sikla solutions. And this has been recently recognized through the Offsite Awards 2021 shortlist!

.png?width=433&name=51222602781_066fb5120f_o%20(1).png)

The Challenge: how was Sikla involved in this project?

Similarly to other EfW projects that Sikla worked in (or are currently being developed), also for the Rookery project we were asked to support with the design & supply of solutions for two main scopes of work:

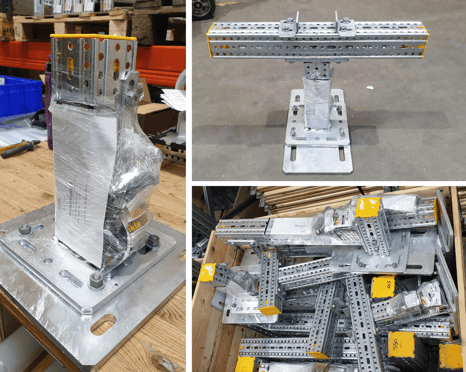

- 12 x Skid frames, e.g. pump skids (feed water, condensates, demi water) and heat exchanger skids

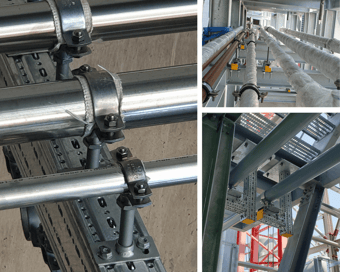

- Piping supports and primary supports for Water Steam Cycle, Balance of Plant and Turbine area. Over 6000 Sikla Pipe Supports were installed!

Our Solutions from the Planning stage to final installation on-site

Firstly, from a Design perspective, there was an in-house Engineering team dedicated to it, equipped with several available software plugins to accurately work to fulfil the customer requirements. The design process was streamlined, took into consideration BIM (Building Information Modelling) and assisted project planning, execution and handover.

Later on, considering the assembly and installation itself, the Offsite benefits of Sikla’s systems were very clear. Modular frames provided the ability to alter frames on-site using only an impact wrench. These structures were designed for making amendments and additions - adjustable components were applied to allow for revisions and building tolerances.

As changes on a construction project are commonplace, it’s worth mentioning that the high level of detail design and preparations for the Rookery South project paid off, because only five small change orders were required after the main scope was supplied. Such low cumulative impact of changes on labour productivity significantly contributed to the success of this project.

Final Outcome and Benefits

Technical Performance

Greater technical performance on the planning and design stage was achieved by taking several steps of continuous development throughout the project and all installation processes. This happens not only with the development of compatible software tools with Aveva products used by the EPC (Engineering, Procurement and Construction contractor), but also through regular discussions and consultations between the teams involved in the construction process.

Prior to starting the design process, the priorities were planned with the EPC, followed by ongoing training, support and consultations with the 3rd party design house - to achieve the most efficient design.

Finally, there was a plausibility check of the design (to assure flawless assembly and installation processes) and debrief discussions were held at the end of the project to gather valuable lessons learnt.

Offsite Best Practices

In terms of assembly/manufacturing itself, using lightweight cordless tools, supplying all components compliant with C4 corrosion resistance requirements and allowing lower transport costs and less human efforts on site (thanks to the average 50% weight saving) lead to high achievements in terms of offsite performance.

Energy Efficiency

The siFramo beam sections are Sikla’s lightweight system and the ones used on the Rookery South project. These beams are up to 50% lighter than traditional steel (weight saving not affecting the beams load capacity), which has - among other benefits - a positive effect on the primary structure of the building. The system is strong but lightweight, cutting down the total tonnage of steel required for the project.

Delivering it on time & on budget

Planning all the processes in an early stage was key to its successful delivery! It allowed all the resources to be allocated for design support, structural calculations and pre-assembly (specifying priorities to deliver the right material at the right time). Also, from the start, we used transparent pricing methods, establishing an accurate preliminary budget.

Regarding the planning methods, consulting with 3rd party design house (subcontracted by the EPC) was important to assure functional and efficient design supported with structural calculations.

Materials wise, all components were C4 compliant – a project requirement - and extremely time-efficient when onsite modifications were required. As a specific requirement, pipe supports for the bottom ash area had C5 corrosion category protection, due to the nature of the ash.

|

Finally, the supplies were available off-the-shelf and the frames pre-assembled by our workshop. Most frames stood below the critical 25kg mark, which made them much more manoeurvable. In some cases, where large frames would be impractical to transport and manoeuvre, a partial pre-assembly took place (with parts clearly labelled and drawings of final assembly). The installers were then able to position & assemble the parts easily, without measuring the parts of each frame. Ultimately, only 10 miles separated Sikla's workshop from the site, providing a unique ability of responsiveness at short notice and uninterrupted progress on site. |

And why was Sikla shortlisted for the Best Use of Steel Offsite Award?

Here are the 5 top reasons:

|

|

So, what about new updates on this topic?

Do you want to be updated on new EfW projects we are working with?

Keep following our news:

Written by Sikla UK Oceania

Comments