By Sikla UK Oceania on 27 March 2023

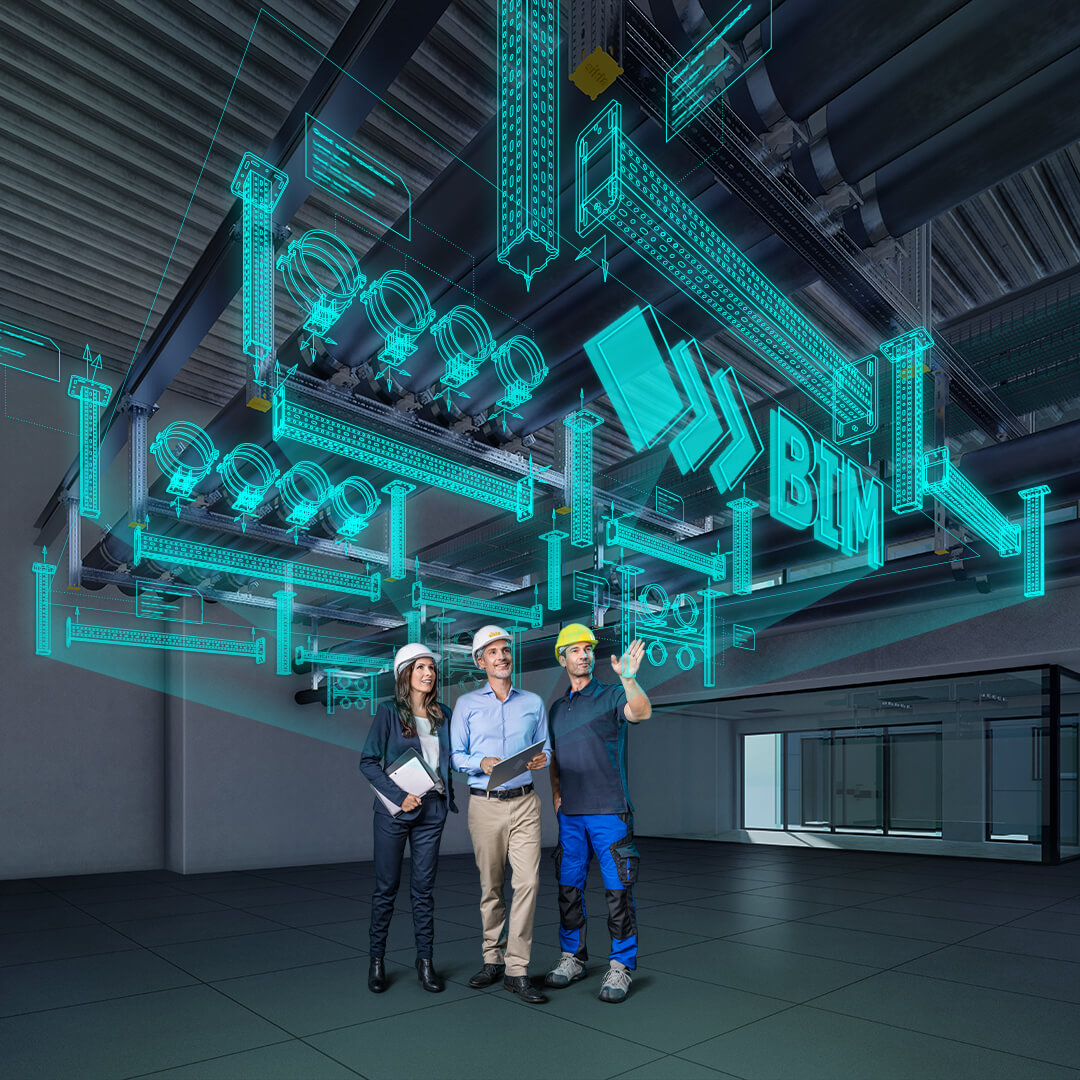

In recent years Sikla has supplied Building Information Modelling (BIM) services to a number of international projects with our software design tools. From the perspective of assessing technical and financial viability, Mechanical & Engineering (M+E) support concepts must be integrated into BIM projects at an early stage. Both material and execution costs can be reduced and a suitable logistical concept can be developed at the right time.

Implementing a project using BIM working methods means working together with all project stakeholders in a collaborative environment. In order to improve the quality of planning and communication within the BIM project, the 3D technical model with all required information and attributes is used as the essential basis.

The 3D master model is created by merging all 3D technical models. The master model can also be used for various analysis purposes, e.g. cost planning and scheduling. However, the benefits of the master model, also known as the digital twin, go beyond the planning and rollout phase and also offer added value during the operation, conversion and decommissioning phases.

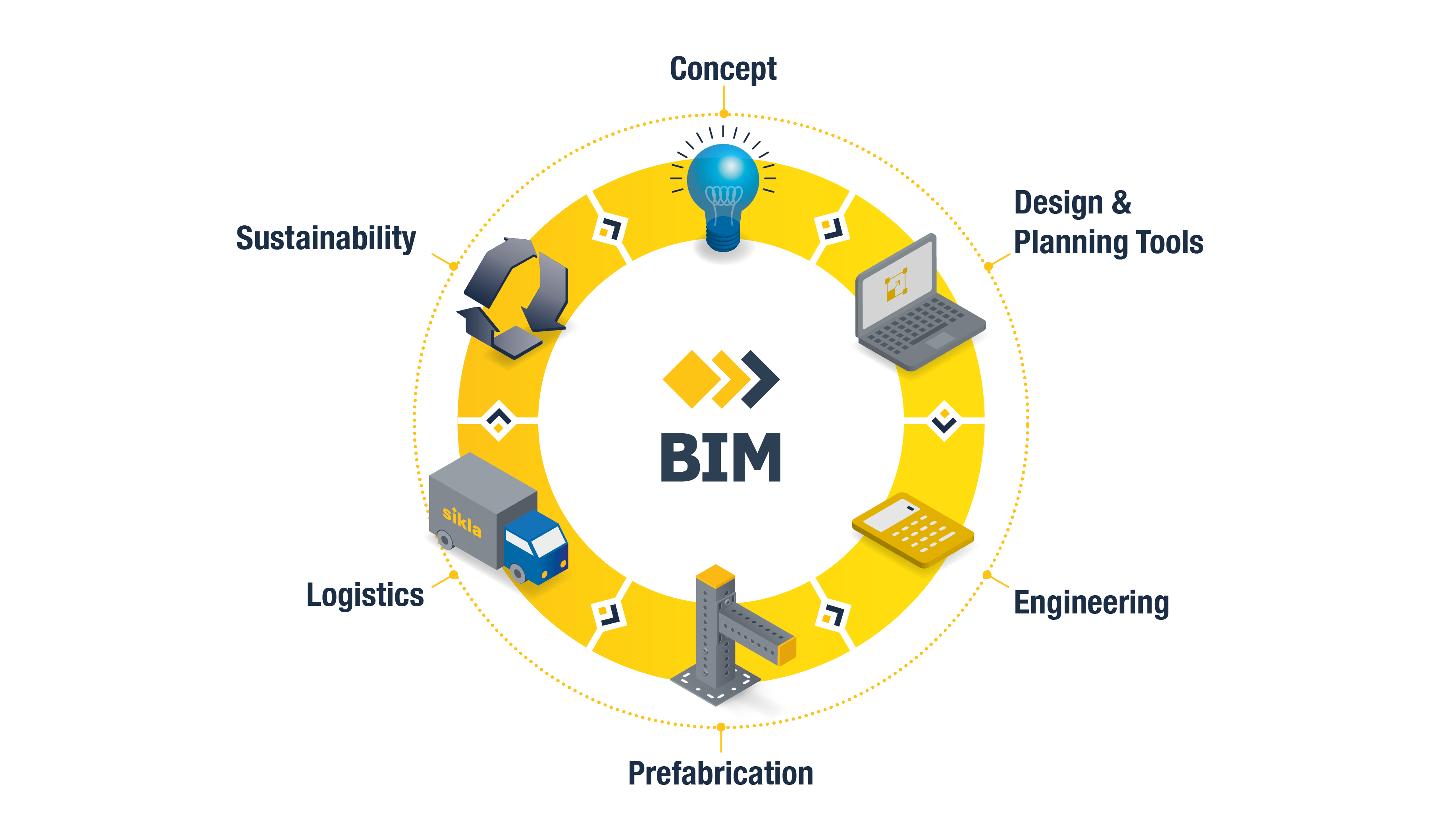

We accompany our customers from conceptual planning through all the following stages, up to personal support on-site. Sikla offers customised BIM services, thus assisting in guaranteeing faster and more economical project execution.

Conceptual Design

At the conceptual design stage, we advise our customers on the appropriate M+E support solutions and promote the benefits of multi-service bracketry design. We offer our BIM services customised to the specific project based on agreed conditions.

Detailing

At this stage, we detail our solutions within the 3D model “Fixings & Supports”. The design selections and concepts are based on project conditions, customer requirements and Sikla’s competence on this subject. The 3D model is continuously screened on its planning quality, depth of information and geometric detail. Where required, supports are being structurally calculated.

Sikla’s tool is a SiCAD4Revit plugin. Part-by-part planning is supported by an add-on module customised to Autodesk Revit. There is a degree of artificial intelligence to simplify and speed up the design of individual supports. To ensure smooth operation, simplified, low-data geometric blocks embody the Sikla components in SiCAD4Revit. The automatic derivation of shop-detailed drawings, including BOM, delivers an additional benefit when putting projects out for tender.

Using the SiCAD4Revit plugin

Project Execution

Detailed BIM integration of supports as described above is key to trouble-free M+E execution. Each project area’s coding is linked with the required supports, allowing Sikla dedicated site deliveries. Flat-packed or fully assembled supports reduce on-site labour requirements. Deliveries are labelled for on-site traceability. If required, containerised consignment stock for spare parts and consumables can be provided. It goes without saying that installation training and site visits for troubleshooting are an integral part of our service.

Revamp

The 3D technical model’s utilisation does not end after the project has been handed over. Buildings don’t last forever and before decommissioning there may be several revamp projects. The 3D model aids these purposes too. The Sikla product’s quality reduces maintenance during operation. All our M+E support systems are compatible with one another and can be easily mothballed for later reuse. With component details integrated with the technical model, pre-analysation prior to decommissioning enables effective recycling. These advantages significantly contribute to the responsible management of resources during all stages of a building’s lifetime.

CAD implementation - Training & Guidance

Do you need any further guidance about these resources?

Sikla offers several tools and services capable of helping you:

- Specification Text Templates

- Software Plug-ins and CAD libraries to implement Sikla components into detailed project design

- Structural calculation reports for worst-case designs (e.g. highest loads/temperatures)

Written by Sikla UK Oceania

Comments