By Sikla UK Oceania on 15 June 2020

Have you been following our blog series about 10 key points of the siFramo Modular Steel System? The previous blog detailed the unique assembly element of this system, Self-Forming Screw.

In this blog we will focus on:

1. Quality control of these siFramo bolted connections and why is it so important.

2. What we recommend as a best practice to ensure the correct tightening of bolted connections in steel structures

3. Can a safe connection be spotted by the naked eye or does it require torque-control?

Role of torque control in the quality check of a safe bolted connection

U.S. military Global Hawk aircraft drone crashed in Afghanistan on the 20th August 2011. Investigators concluded the cause of the accident was an improperly torqued fastener. Luckily, no casualties were involved, but it costed millions to learn this lesson.

Any standard bolt that may look tightened might in fact not be. In that case the connection would ultimately get lose by vibration in any form. The siFramo self forming screw FLS however provides an unprecedented level of safety because when the naked eye can see that it has been used, it proves already that it will do 90% of the job. This is because it cannot come out on its own nor by any vibration. It is in this regard neither dependent on a washer, a nut or even a counter nut but entirely on its own vacuum sealed thread connection.

To assure full compliance with Eurocode 3 (EN 1993) for "Design of steel structures", which Sikla uses as basis for calculation to determine load capacities, it's important to follow specified tightening torques and perform torque checks on regular basis.

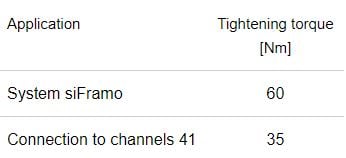

siFramo Self-Forming Screw tightening torque specifications

How to torque check a bolted joint?

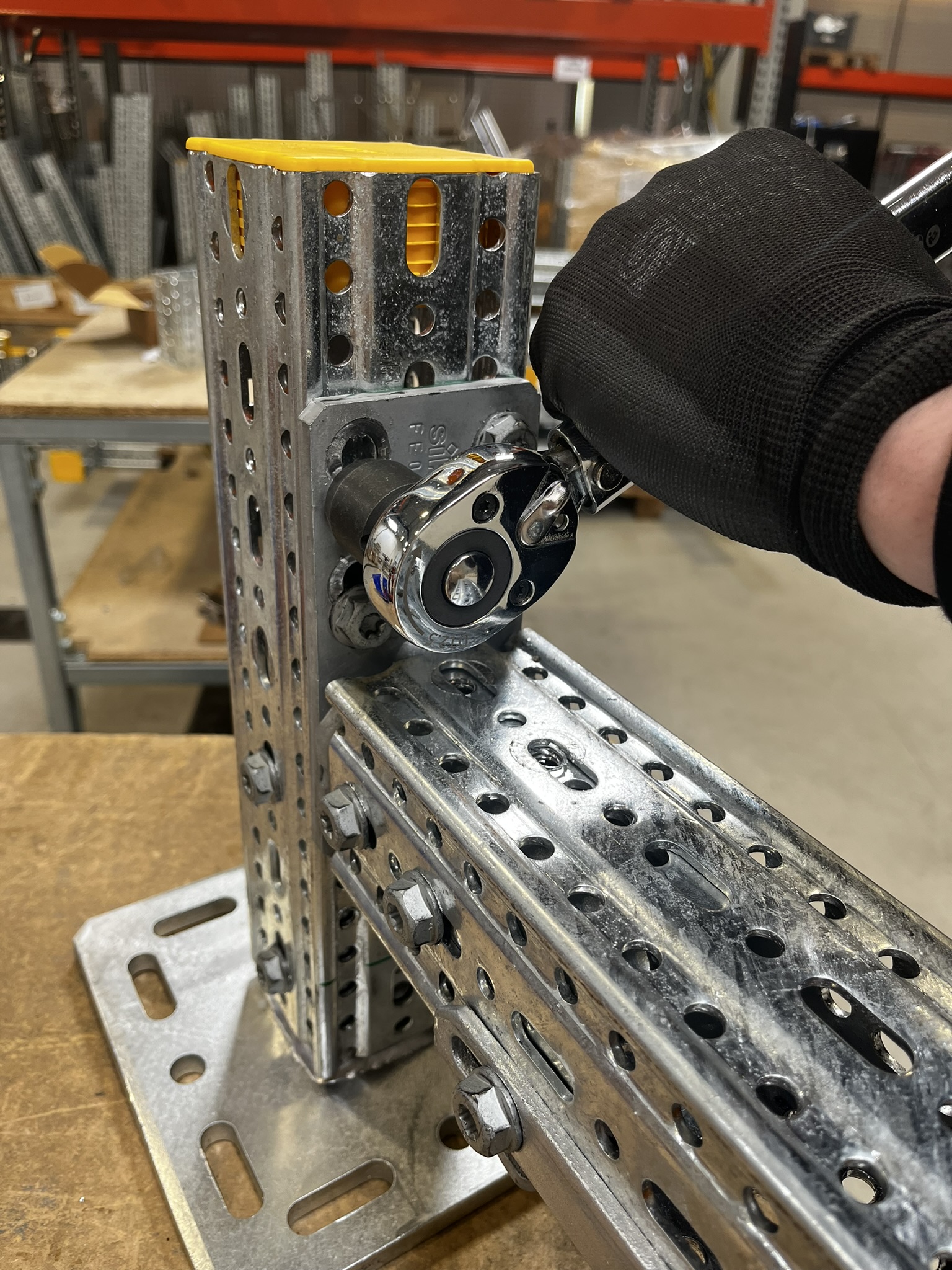

Torque measurements can be done via static or dynamic methodologies. The first one states that the bolted connection torque control is performed after the tightening, often with a torque wrench. The dynamic method refers to torque measurements performed during the tightening, using a power tool, such as an impact driver. At Sikla, we recognise the importance of both methods in our own prefabrication process. We use cordless digitally controlled impact wrenches to achieve consistent results and our technicians perform regular quality audits using calibrated torque wrenches.

Impact wrench and Calibrated torque wrench

Impact wrench and Calibrated torque wrench

Some of the benefits of using cordless digital impact wrenches which we recognize are:

- Efficient assembly process

- High precision

- Transparent torque audit reports

So why use Sikla?

As part of our service, we supply frames prefabricated in our certified quality-controlled environment. All CE marked systems are subject to the certified factory production control according to EN 1090 and may therefore be used to EXC 2 for load-bearing structures.

.jpg?width=545&height=363&name=052%20(1).jpg)

Prefabrication process

Prefabricated frames ready for dispatch

Prefabricated frames ready for dispatch

Alternatively, we can provide advice on selection of the right tools to help you work with precision and efficiency.

Coming up next - don't miss it:

- Do the connection elements keep the frame corners clear, i.e. 100% of section area can be used as a support?

- Can connections be made steplessly and fixing positions are not dependent on availability of holes and slots?

- Is independently tested load data available for all components and parts of the system?

- Is test data available for typical frame configurations and based on all 3 possible load directions?

- Is the system BIM and plant design software compatible?

- Can the system be calculated with a 3D structural frame analysis program?

- Is a global manufacturer accountable for the product?

Are you interested in the siFramo system and want to know more about how it could benefit your project?

Written by Sikla UK Oceania

Comments